Replacement motor keeps Swedish paper mill running

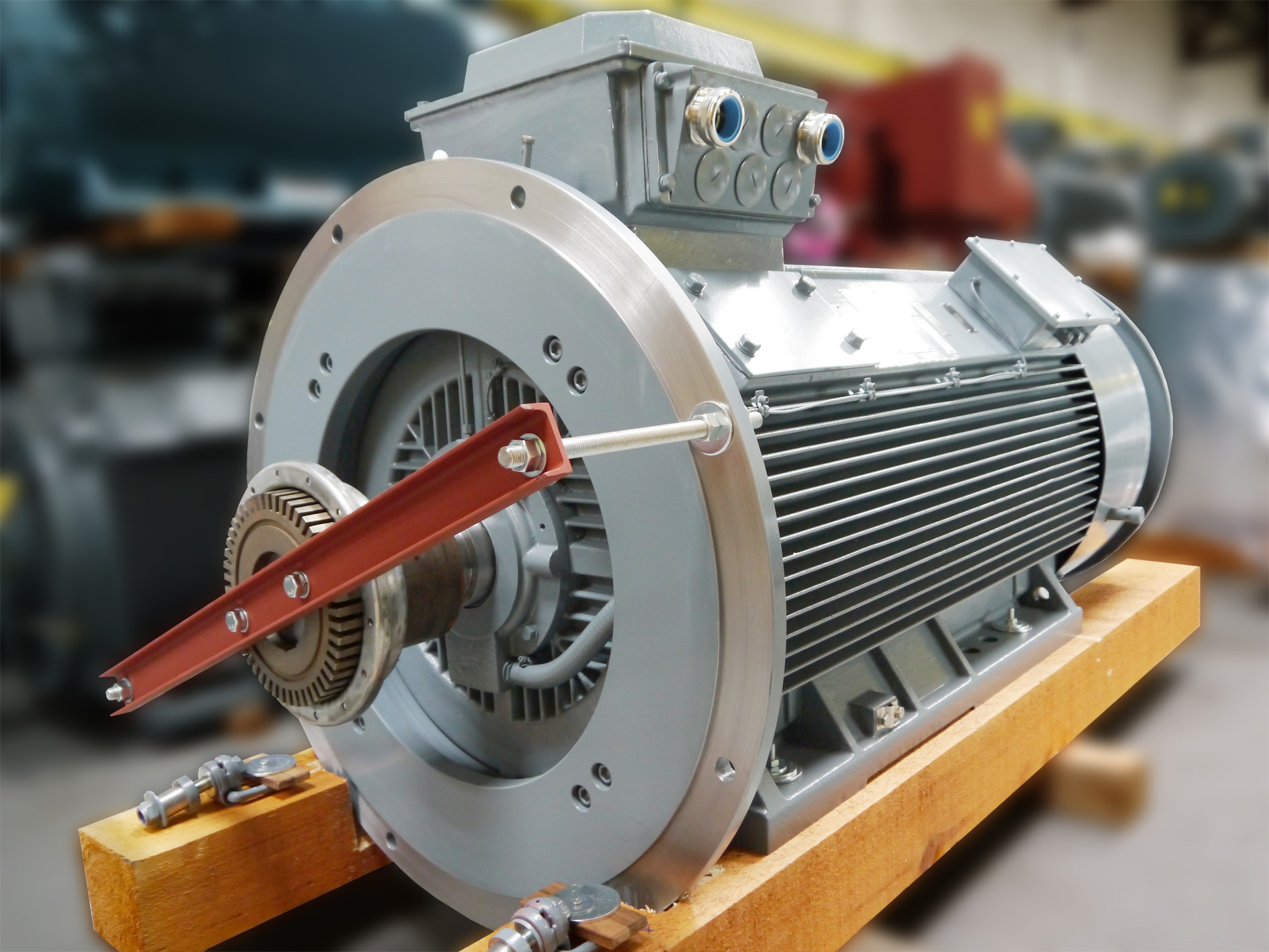

When a compressor motor failed at a Swedish specialty paper mill, Menzel Elektromotoren delivered the urgently needed replacement drive: a 4-pole squirrel cage motor with 710 kW, 6000 V rated voltage and a speed of 1489 min-¹. The original motor was a custom-made Siemens unit that was no longer available. Menzel therefore modified a stock motor prior to shipment to match the B35 design of the original squirrel cage motor. This meant construction and installation of a flange as well as manufacturing a mounting option to accommodate a support foot.

In addition, the shaft of the squirrel cage motor had to be turned down to 110x210 mm. Menzel engineers carried out the modifications within a week, allowing for a quick replacement of the old motor. Drawing on an extensive range of motors kept in stock as well as on 90 years of experience in constructing application-specific drives for clients from a diverse range of industries, Menzel are able to quickly and reliably process urgent requests for such custom designs. For many clients, this service is absolutely crucial to avoid severe interruptions in production due to downtime.

Technical characteristics squirrel cage motor:

- Type: MEBKGR400-04

- Rated Power: 710 kW

- Voltage: 6,000 V

- Frequency: 50 Hz

- Poles: 4

- Rated Speed: 1,489 min-1

- Mounting: IM B35

- Protection: IP 55

- Cooling: IC 411

- Weight: 4,000 kg