8,500 m² effective floor space in Hennigsdorf

When complete, the new motor plant in Hennigsdorf will have an effective floor space of 8,500 m². The production area will accommodate the assembly, metal processing, fabrication and winding workshops, paint shops and three state-of-the-art test fields. In addition, there will be roomy offices, logistics zones and storage areas. Completion of the new plant is scheduled for summer 2023. All administrative and production workplaces are to be relocated by January 2024.

The move heralds a new era for our motor company, which was founded in 1927. Menzel manufactures three-phase asynchronous motors with squirrel cage or slip ring rotors up to 20 MW and DC motors up to 2 MW. We offer several powerful own-brand motor series, and we specialize in customization as well as identical replication of existing motors. Menzel keeps various motor versions up to 15 MW permanently in stock and adapts them at short notice for a wide variety of applications and locations.

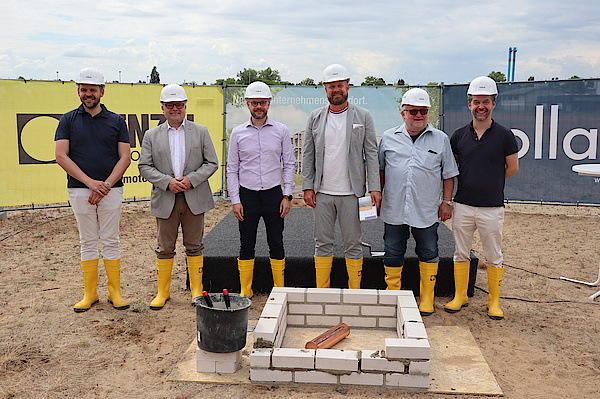

Laying of the foundation stone

The ceremonial laying of the foundation stone took place on June 11, 2022. More than 200 guests were present and watched as the managing directors of MENZEL together with the project manager Paul Bernhardt, the mayor of Hennigsdorf Thomas Günther and Mathias Jordt from the construction contractor Vollack bricked in a time capsule. The Vollack Group, an expert in methodical building conception, oversees planning and construction. Read more and watch the film of the of the foundation stone ceremony!

The sky is the limit

Now that the foundation pits have been excavated and prepared accordingly, the heavy-duty trucks with the prefabricated ferro-concrete columns are rolling into Hennigsdorf.

The supporting structure for the office building and the halls is being erected piece by piece, and soon the true dimensions of our new plant will become apparent.

Columns and trusses are being erected bit by bit

In the meantime, the first ferro-concrete trusses have been lifted by crane into place and assembled. They connect the columns to each other. So the "skeleton" of the buidling will soon be ready.

A dry summer in Germany is allowing the work to progress quickly, even if the hot summer temperatures are making the teams on site sweat a lot.

The first wall is up!

Construction work is progressing well and the first wall of the new workshop is already in place. In addition, the foundation for the three-story office building has been poured. In the future, this will house all offices, a canteen as well as changing rooms and sanitary facilities.

The walls of the northern hall are in place

The walls of the northern production hall are almost all in place, revealing the size and ceiling height. In parallel, the foundation pits for the prefabricated ferro-concrete columns for the southern hall are being prepared.

In the foreground, the first walls for the office building are being placed. A three-story office building, the main entrance and a cafeteria will be built here.

This is what the facade will look like!

During today's site inspection, we were allowed to take a first look at the exterior facade of our new factory halls. In the picture you can see the northern production hall.

The facades consist of so-called finished steel sandwich elements, which will be installed horizontally. The elements consist of an outer and inner formwork of micro-lined steel sheets and an insulating core. The color of the outer facade is RAL 7016 anthracite. The height of the attic is 11.65 m.

First floor of the new office building completed

Now all supporting columns for the southern factory hall are in place. In addition, the first floor of the new office building is complete and the facade segments for the 1st floor have already arrived. It won't be long now before our employees can take a look at their new workplaces on site.

Foundation for the new load test field

Here you can see the two meter deep concrete foundations for our new load test field. In the near future, routine, type and system tests will be carried out here - also for external customers and electric motor brands. We test electric motors, generators, synchronous machines or transformers, converters and motor systems.

Paramenter of the new test field:

- Test voltage: up to 13.200 V

- Frequency: up to 120 Hz

- Power: up to 2.300kVA

- Crane capacity: up to 80t

- Hook height: 7,5m

- Two test beds: 12x5m and 9x3m

The first walls of the upper floor are in place

In the meantime, the second floor of the office building is finished and the first walls of the upper floor are in place. Soon we will be able to invite our employees to walk through the future halls and offices for the first time. This will be exciting!

The southern factory hall is also already getting its outer facade consisting of so-called, finished steel sandwich elements. The elements consist of an outer and inner formwork of micro-lined steel sheets and an insulating core.

Topping-out at new Menzel motor plant

Only six months after the laying of the foundation stone, we celebrated the topping-out of our new headquarters on 16 December 2022. The ceilings were completely closed and, as it is a tradition in the German construction industry, a topping-out crown now graces the building. A real carpenter and employee of the executing construction company Vollack held the topping-out speech dressed in traditional carpenter's uniform from the top of the scaffold. No easy task in sub-zero temperatures! A toast to the builders, the craftsmen and the architects!

Menzel employees enter the new plant for the first time

After the official ceremony, our employees were allowed to enter the buildings for the first time and see the dimensions for themselves: 24,000 m² plot will accommodate approx. 8,500 m² of production area, along with spacious offices and a cafeteria. The new factory will feature the capacity to manufacture and test larger, heavier drive systems.

The floor plate is being made

Meanwhile, the roof of the hall has been totally closed. Now the floor plate is being made, which is a very intense physical work. Besides that, a lot more is happening right now, e.g. all the awnings on the outer facade are being installed. And also our future test field is taking more and more shape. So it's definitely worth checking in here from time to time to see the progress.

The interior work begins

Now that the first partition walls in the office building have been erected, it is time for the final selection of materials for floors, walls, kitchen and furniture fronts. Not an easy task, considering how many options there are and how large the market of materials is. Our employees can look forward to the results!

View into the southern production hall

Here you can see the new southern production hall, once from the office side and once from the test area side. The partition wall seen in the front area will be fitted with a large sliding door in the center. It is used in particular for work safety and reduces the noise level during motor tests for the rest of the hall. Since the partition wall does not reach up to the ceiling, our cranes with a crane capacity of up to 80 tons can drive right up to the test area - in future, this will mean a huge time advantage thanks to the optimized intralogistics routes!

In addition to the actual load test bay and the offices for our test field technicians, the two-story massive installation in the load test field will also offer a modern customer lounge. Floor-to-ceiling windows allow our customers and guests to comfortably follow the motor tests live from there.

Delivery of the 57 ton transformer station

Last week our new transformer station was delivered. It weighs 57 tons and will supply our entire plant with sufficient electricity. The transformer station with its 15000 volt connection is divided into three parts. Two transformer units convert the 15000 V to 400 V for redundant supply of the factory. The third part with its own feeder and fuse protection at 15 kV level goes directly to the electric motor test field.

Come in, so you can look out!

As the saying goes: Come in, then you can look out. The windows in the office building are in and give an idea of the view that our people will soon have from their desk.

The interior finishing work is in full progress, as the dry walls have already been put in place.

Protective and partition walls have also been installed in the production hall, which will, for example, reduce noise during the production process of our motors.

MENZEL subsidiary companies visiting

Last Friday, we had our first official visit to our construction site. Representatives of our international subsidiaries from France, Italy, Sweden, Great Britain and Romania were guests in Berlin and were very impressed by the new MENZEL production halls and offices in Hennigsdorf.

It's getting real...

Today there is an all-round look at the interior work, which continues to progress! Heavy-duty racks, which will house parts of our huge motor stock with a storage area of about 1,500 square metres, are now in the southern hall; the paint booths are continuing to take shape, as are our new test fields: In addition to the area for our test field technicians, a separate room for customers with a direct view of the test fields is being built in a two-storey extension. The offices are also shining and are looking forward to being occupied by the MENZEL team soon.

Powerful cranes and affectionate names

In order to be able to navigate our heavyweight and very large electric motors through the production hall in the future, the new plant in Hennigsdorf features two overhead travelling cranes, each with two trolleys of 20 tons. In combination with both crane bridges and all four trolleys, we will thus be able to lift up to 80 tons, which will make the production process much more agile.

Below the bridge cranes in the production hall, we have installed five semi-gantry cranes, each with a trolley with a load capacity of 5 tons. The semi-gantry cranes are more maneuverable and faster for "lighter" motors and components, although "light" is just a relative term here.

Further to this there are another three bridge cranes in our large warehouse, each with two trolleys á 20 tons. The crane called "Super Master Crane" can run in tandem with the left and right crane bridge and thus also has a total load capacity of 80 tons.

This means we are ideally prepared for larger motor frame sizes and heavyweights!

The first motors are moving to the new factory

Although we will not officially receive the key to the new plant until the next few days, our electric motors have been moving from the old site to the new plant for weeks now. When moving one of Europe's largest warehouses of large electric motors, this can take several weeks. Our colleagues in the logistics department have their hands full, because the normal shipping business is continuing as usual.

In the meantime, preparations are already being made in the offices and in production for the move, because from January 1, 2024, we will all be working completely at the new site.

Our customers can be assured that electric motor production will continue as normal at any time.

Now it's time to pack boxes!

While the finishing touches are being made to the new building, our offices are already busy packing boxes. We are being supported by a professional moving company, as we will of course continue to be available for our customers and business partners in the coming weeks.

A lot has accumulated in our almost 100-year company history. We are excited about the one or other historical find, which will be given a place of honor at our new location.

The plan is to complete the relocation of all workstations in production and the offices in December 2023, so that we can close the old site over the Christmas holidays - with one crying and one laughing eye.

Ribbon-cutting ceremony after just 17 months of construction

New Menzel motor plant completed! After just 17 months of construction, the moment had finally come on November 15, 2023: We received the keys to our new MENZEL headquarters in Hennigsdorf on the outskirts of of Berlin. Our Managing Directors Mathis Menzel and Dirk Achhammer and our Construction Project Manager Paul Bernhardt officially inaugurated the new buildings with a small ribbon-cutting ceremony together with Thomas Schreck and Matthias Jordt from the construction company.

All works were completed on time and on budget – a remarkable feat of coordination between all trades and partner companies. The move has already started; the relocation of the large stock of motors and accessories, in particular, will take some time.

Operations will officially start on January 2, 2024. From there on the MENZEL headquarters will be available exclusively at our new address in Hennigsdorf:

MENZEL Elektromotoren GmbH

Am Alten Walzwerk 2

16761 Hennigsdorf (Germany)

Of course, the inauguration of our new company headquarters will also be appropriately celebrated. To ensure that we can host our official inauguration party with a particularly large number of guests, we will postpone it until spring 2024.

Contact details

For your questions, please contact Paul Bernhardt, business unit manager and construction project supervisor Menzel Elektromotoren GmbH, Tel: +49 30 349 922-140 or email: pb@menzel-motors.com.