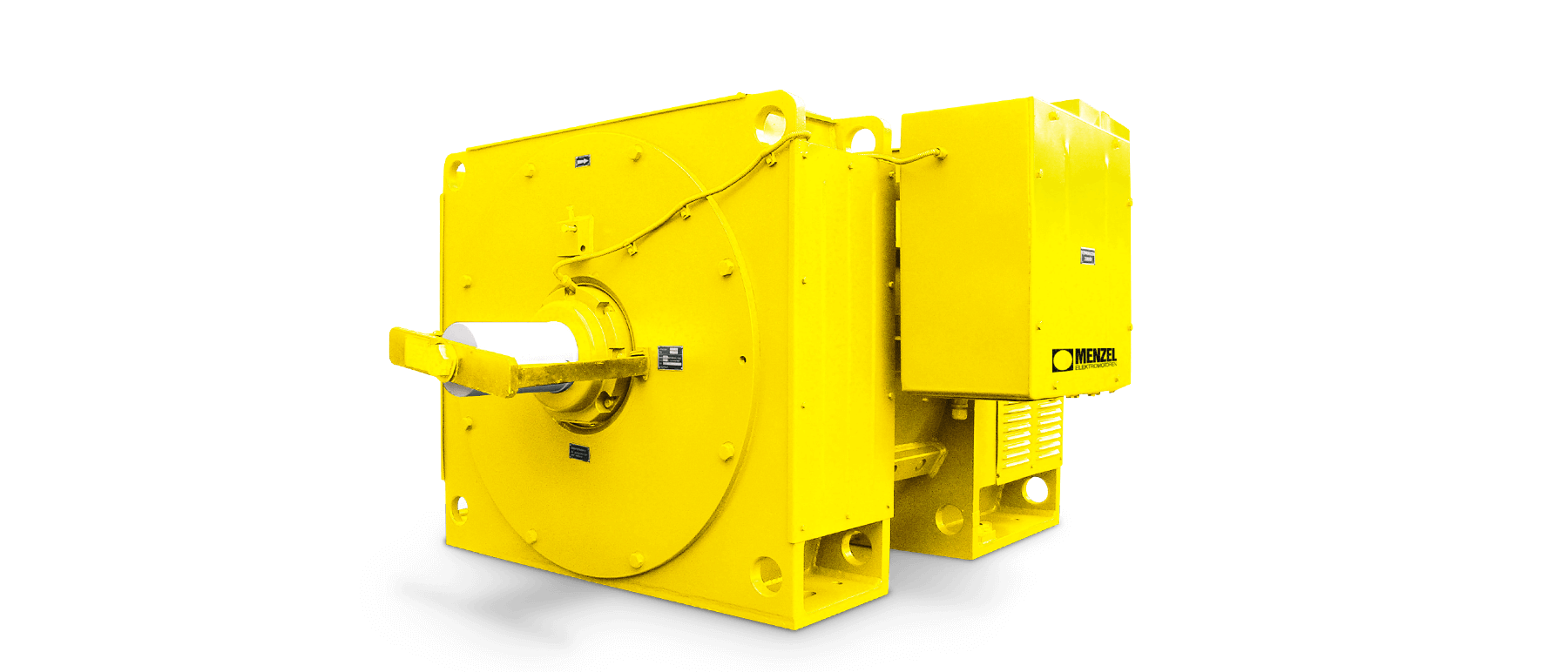

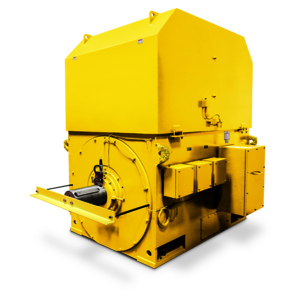

Water cooled squirrel cage motors (IC 81W and IC 86W)

MENZEL water-cooled squirrel cage motors are especially powerful, compact and extremely quiet. Our squirrel cage motors are available for low-voltage from 75 kW as well as medium and high voltage up to 25000 kW.

MENZEL water-cooled squirrel cage motors are especially suitable for industrial applications with harsh operating environments and restricted spatial conditions. Due to their compact designs, cooling types IC 81W and IC 86W (air-to-water heat exchanger) allow increased motor power and optimal vibration damping. MENZEL water-cooled squirrel cage motors comply with protection classes IP 23 and IP 55 in accordance with DIN IEC 34, Section 5, whereby alternative protection classes are available on request.

As well as our water-cooled squirrel cage motors, we offer three-phase asynchronous motors of the following cooling types: IC 01, IC 06 (open-circuit ventilated), IC 411, IC 416 (rib-cooled/surface-ventilated), IC 511 (pipe-cooled) und IC 611, IC 616 und IC666 (air-air cooling).

Standard designs of water-cooled squirrel cage motors (IC 81W + IC 86W)

- Construction type: IM B3, IM V1 (special designs possible at any time)

- Protection classes: IP23, IP 55, IP 67

- Voltage: from 380 V to 13800 V

- Power range: up to 25000 kW (25 MW)

- Frame size: from 315 to 900

- For grid and inverter operation

- Terminal box: above, rotatable by 4 x 90°, sideways optional

- Motor housing: Gray cast iron or welded steel

- Thermal utilization: F/B

Application-specific special designs of our water-cooled cage motors are available on request at any time.

Available voltage ratings for water-cooled squirrel cage motors

Our water-cooled motors with squirrel cage rotors are available for different nominal voltages. We are able to implement all special voltages or deviating voltage tolerances on request.

Nominal voltage at 50 Hz

- Low voltage: 380 V, 400 V, 440 V, 480 V, 500 V, 525 V, 575 V, 690 V

- Medium and high voltage: 2.300 V, 4.160 V, 6.000 V, 6.600 V, 11.000 V, 13.200 V, 13.800 V

Nominal voltage at 60 Hz

- Low voltage: 380 V, 400 V, 500 V, 690 V

- Medium and high voltage: 3.000 V, 3.300 V, 5.000 V, 5.500 V/ 6.000 V, 6.300 V, 6.600 V, 10.000 V, 10.500 V, 11.000 V

Advantages of water-cooled squirrel cage motors (IC 81W and IC 86W)

Very quiet, because there is no external fan. Suitable for extreme environmental conditions

Highly efficient cooling, and therefore high performance and torque density

Cooling even when the motor is not running

Small motor size possible, due to high rotational speeds

Interior protection through the encapsulation of the motor

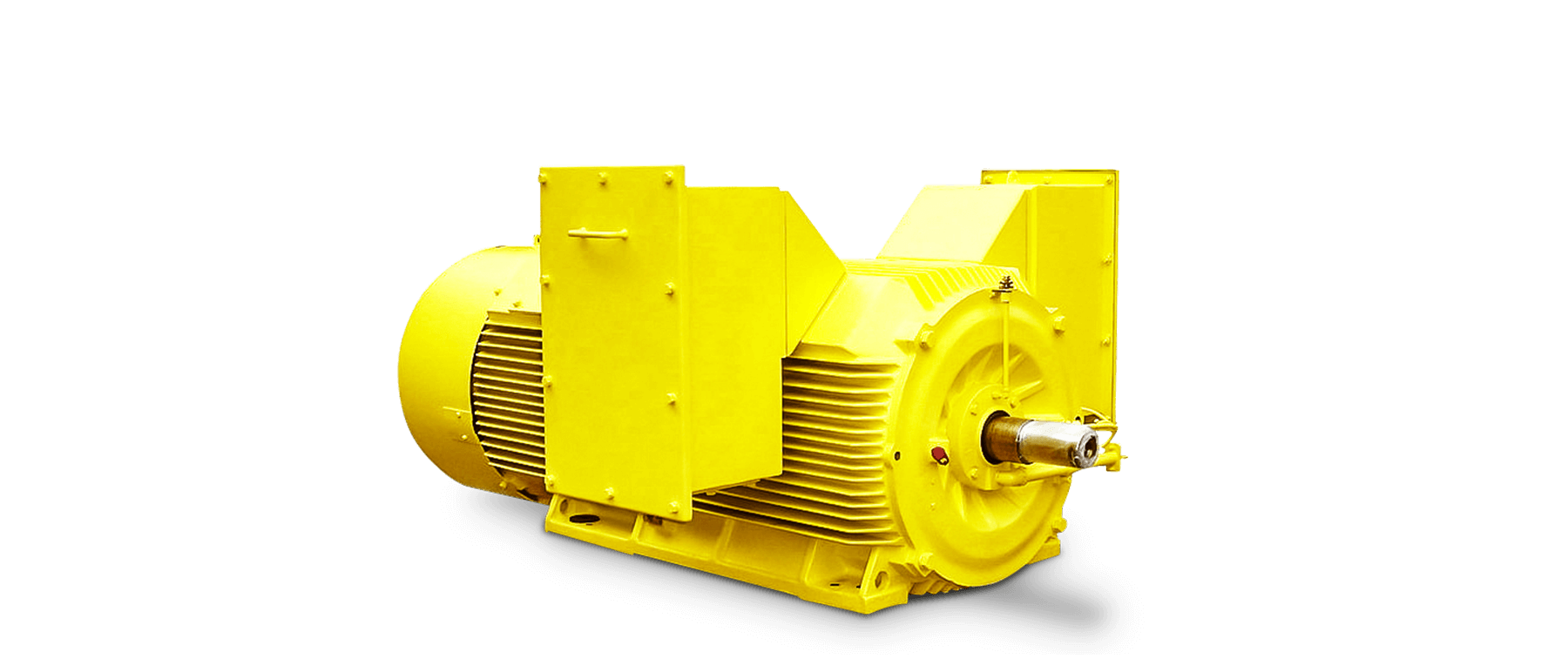

Modular motor design: Air-water cooling (IC 81W + IC 86W) – Characteristics

MENZEL squirrel cage motors with air-water cooling have a modular design, and are manufactured for low, medium and high voltage applications. In our modular MEBKSW series, we offer squirrel cage or short-circuit motors with flexible designs.

The basic design of our modular MEBKSW air-water cooled motors is primarily identical, and therefore ensures lower production costs. Simultaneously, it enables us to offer several protection and mounting types. Therefore, our motors with air-water cooling can be adapted for all possible industrial uses.

Typical uses for water-cooled squirrel cage motors (IC 81W and IC 86W)

Water-cooled squirrel cage motors are primarily used in areas where extreme environmental conditions prevail. This applies, for example, to industrial plants in which a lot of dust, fibers, rubber particles, and abrasive materials or particular effects of dirt or moisture.

Water-cooled squirrel cage motors are also used in industrial and production plants with heat recovery. The waste heat produced by the motor can be reused. Other common areas of use are plants with increased room or radiation temperature, or plants in air-conditioned areas in which the dissipated heat cannot be transferred directly to the environment, such as compressor stations, test areas, or compressor rooms.

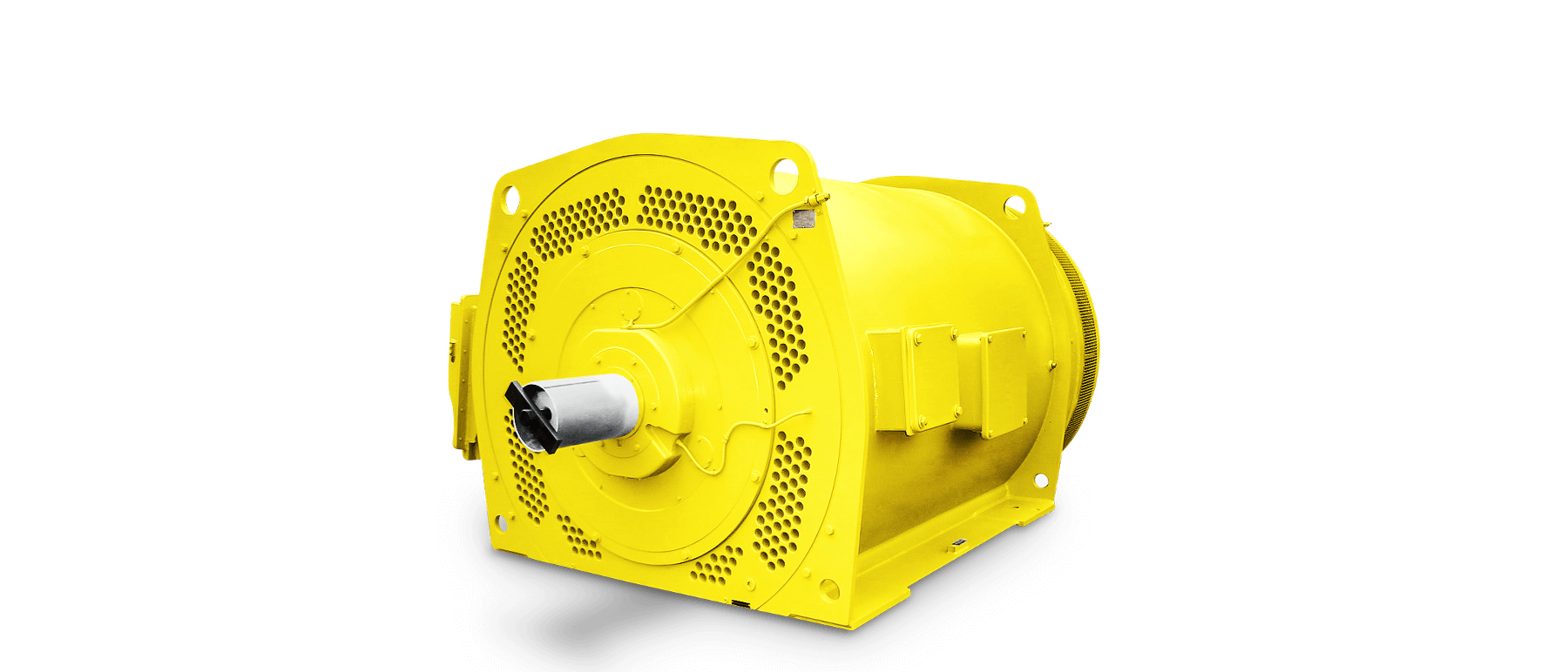

The air-water cooling principle

According to the air-water cooling principle, water is the main coolant. It flows in a closed circuit, and transfers heat to the secondary coolant (the air), via a so-called air-water heat exchanger. For this purpose, waveguides or cooling pipes are installed, through which the purified water flows.

The material of the cooling pipes and water tanks depends on the quality of the cooling water. The inner cooling circuit is separated from the environment by seals, pursuant to the motor protection class. The motors can also be easily used in harsh environments, and can withstand external effects.

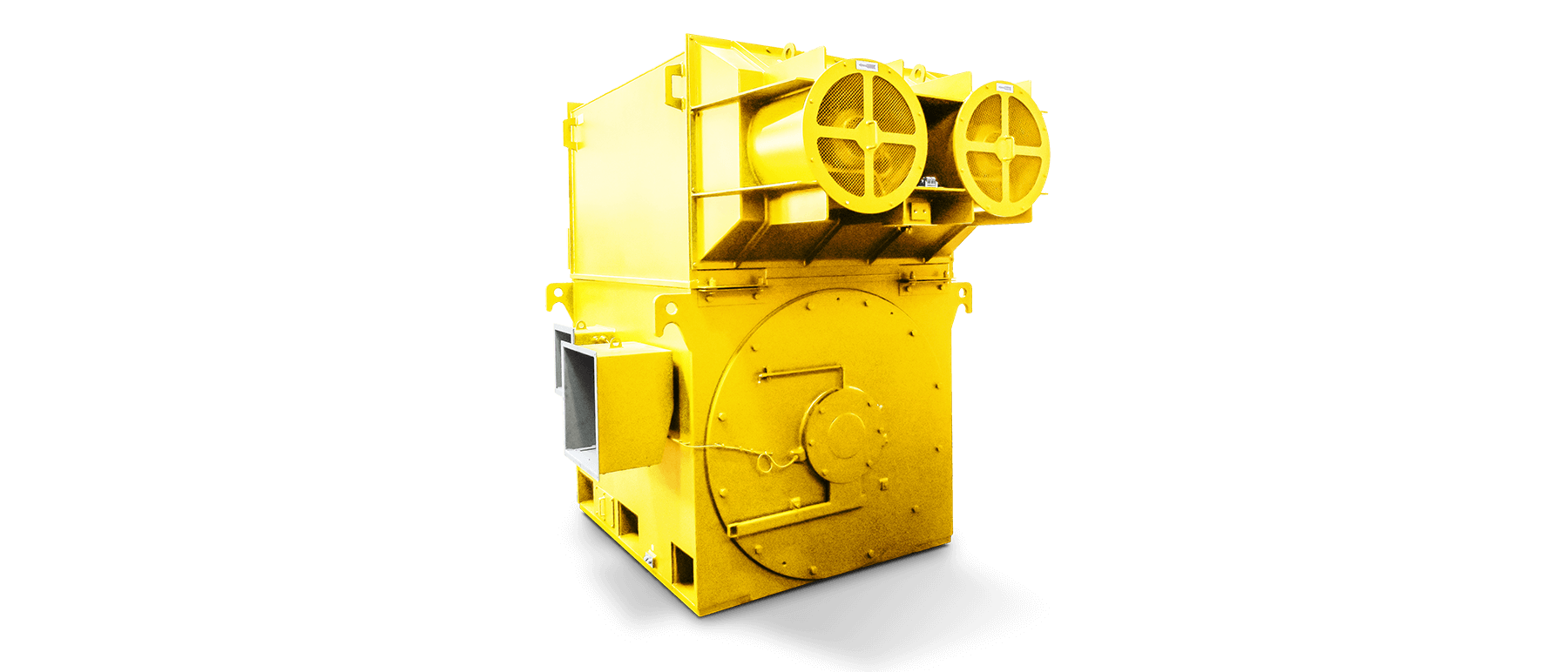

Air-water cooling IC 86W

In air-water cooling, the internal cooling circuit can also be powered by an independent ventilation unit in the hood. If this is the case, the squirrel cage motor corresponds to cooling type IC 86 W and is suitable for variable speeds.

Air-water cooling IC 81W

The heat generated in the motor (stator and rotor) is fed into the air-water heat exchanger by an internal fan in the internal circuit. The air-water heat exchanger cools the internal air flowing through it to the required temperature.

Are you looking for a water-cooled squirrel cage motor for industrial use? MENZEL offers an extensive range of industrial motors, and delivers quickly and reliably all over the world.