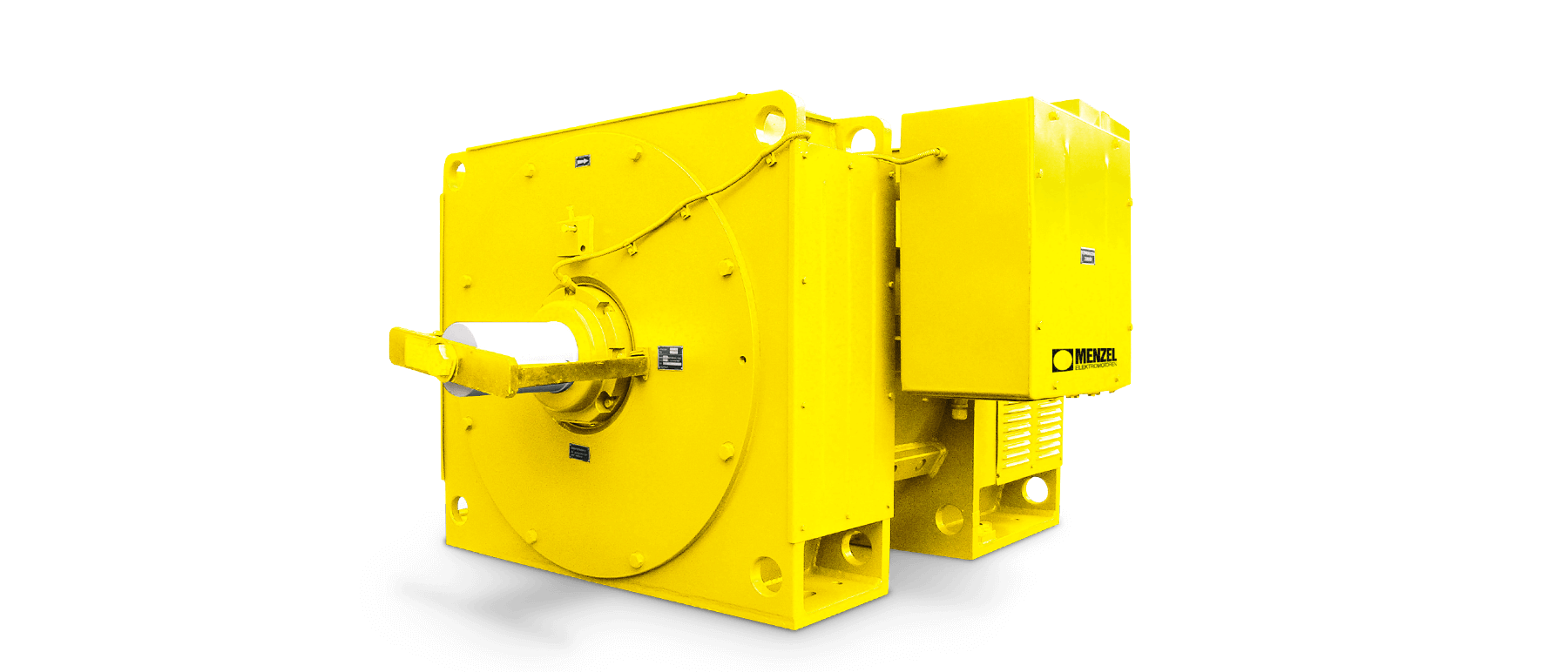

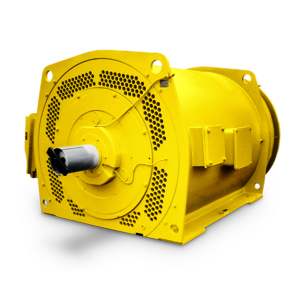

Low and high voltage squirrel cage induction motors

Low and high voltage squirrel cage induction motors, of cooling type IC 511, are part of MENZEL’s tailor-made product range for your industrial applications

MENZEL produces low, medium and high voltage squirrel cage motors of all cooling types. According to the industrial application, we deliver open-circuit ventilated (IC 01 + IC 06), surface-cooled (IC 411 + IC 416) or pipe-cooled (IC 511) motors and squirrel cage motors with air-air (IC 611 + IC 616 + IC666) or air-water cooling (IC 81W + IC 86W) around the world.

The housing design or IC 511 cooling was previously a widely-used standard design for low and high voltage three-phase squirrel cage motors. However, it has gradually been replaced by more modern cooling types such as IC 411 and IC 611, MENZEL Elektromotoren still builds squirrel cage motors of the old cooling type, IC 511, as these are still the first choice for industrial applications, due to their various advantages.

Standard designs of IC 511 three-phase squirrel cage motors

- Construction types: B3 and V1

- Protection classes: IP 55

- For grid and inverter operation

- Voltage: from 380 V to 13800 V

Power range: up to 4000 kW

- Frame size: from 500 to 1000

- Terminal box: generally possible

- Motor housing: Welded steel

- Thermal utilization: F/B

MENZEL specializes in producing special custom-made products for all kinds of industrial applications. If you are looking for drive solutions in the field of pipe-cooled squirrel cage motors (IC 511), please do not hesitate to contact us.

Available voltage ratings for three-phase squirrel cage motors

MENZEL supplies three-phase squirrel cage motors for various nominal voltages. We can implement all special voltages or deviating voltage tolerances on request.

Nominal voltage at 50 Hz

- Low voltage: 380 V, 400 V, 500 V, 690 V

- Medium and high voltage: 3.000 V, 3.300 V, 5.000 V, 5.500 V/ 6.000 V, 6.300 V, 6.600 V, 10.000 V, 10.500 V, 11.000 V

Nominal voltage at 60 Hz

- Low voltage: 380 V, 400 V, 440 V, 480 V, 500 V, 525 V, 575 V, 690 V

- Medium and high voltage: 2.300 V, 4.160 V, 6.000 V, 6.600 V, 11.000 V, 13.200 V, 13.800 V

Advantages of our IC 511 low and high voltage squirrel cage induction motors

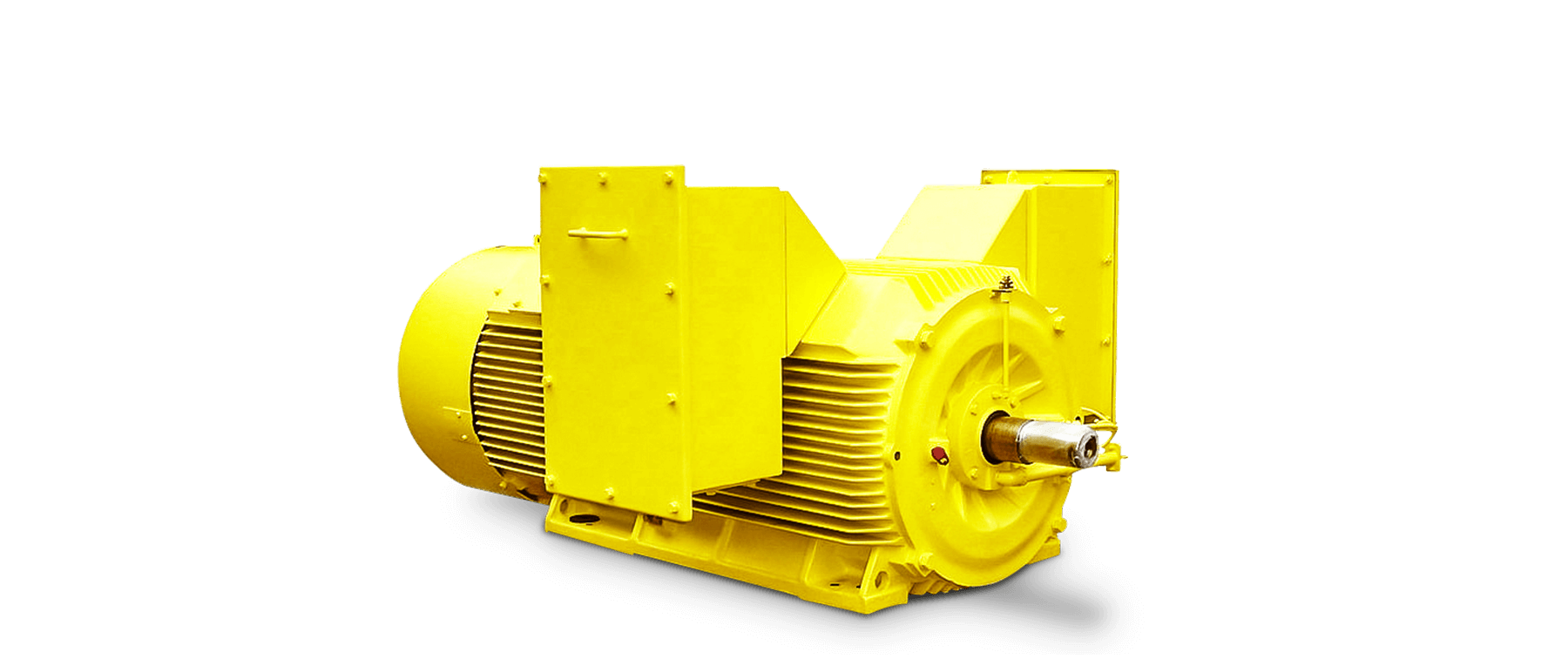

Robust motor design with round, smooth surface

Resistant to external influences, due to torsion-resistant welded steel housing

Flat construction height and reduced overall length

Long machinery lifespan

High load capacities

Vibration resistant

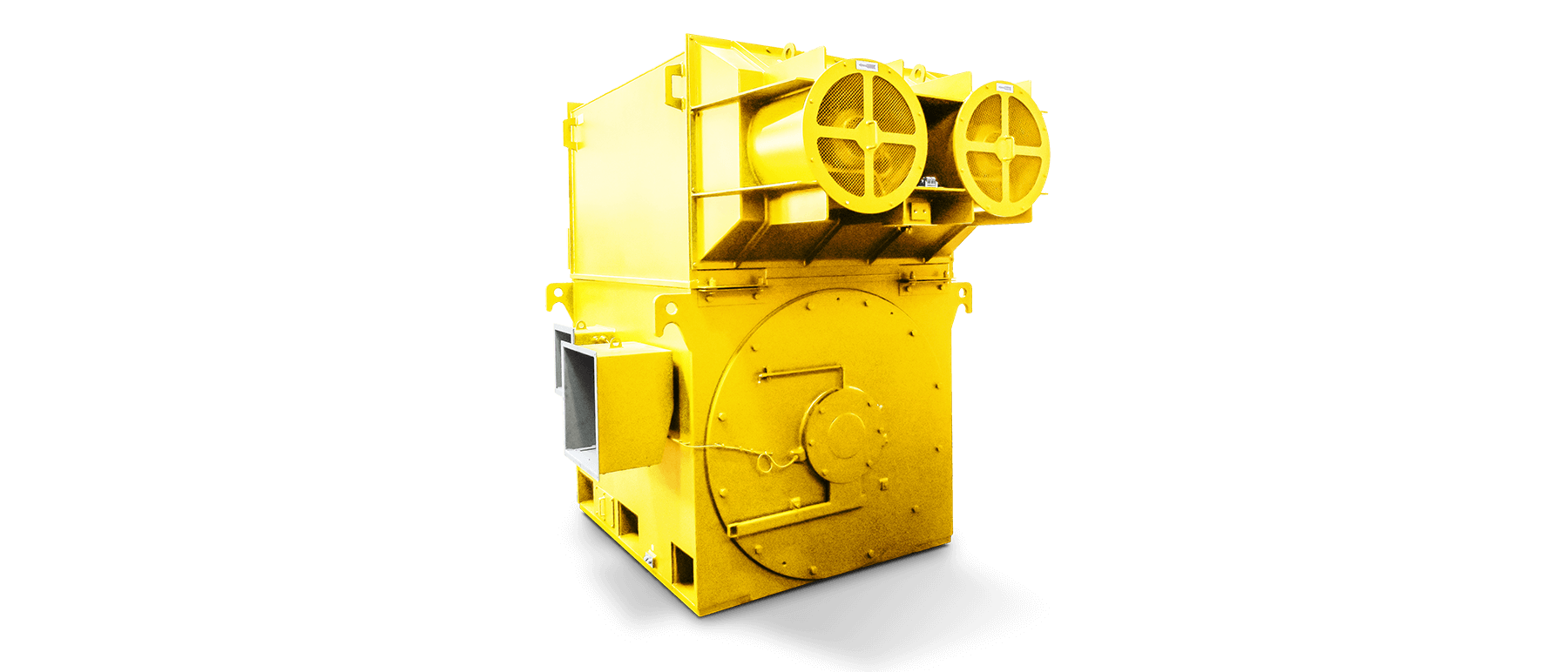

Excellent, simultaneous air cooling

No blockages in the cooling pipes

IC 511 squirrel cage induction motors – Characteristics

For IC 511 squirrel cage induction motors, the cooling pipes are wound symmetrically around the laminated core. This construction type offers a whole spectrum of advantages: Falling materials simply slide off the smooth, rounded surface. Unlike with other cooling types, the cooling fins cannot be blocked.

In addition, the distribution of the cooling pipes or cooling tubes around the laminated core leads to a generally flat overall height for motors of cooling type IC 511, which is why such motors are ideal substructures for various machines. Their short overall length makes the motors more vibration-resistant.

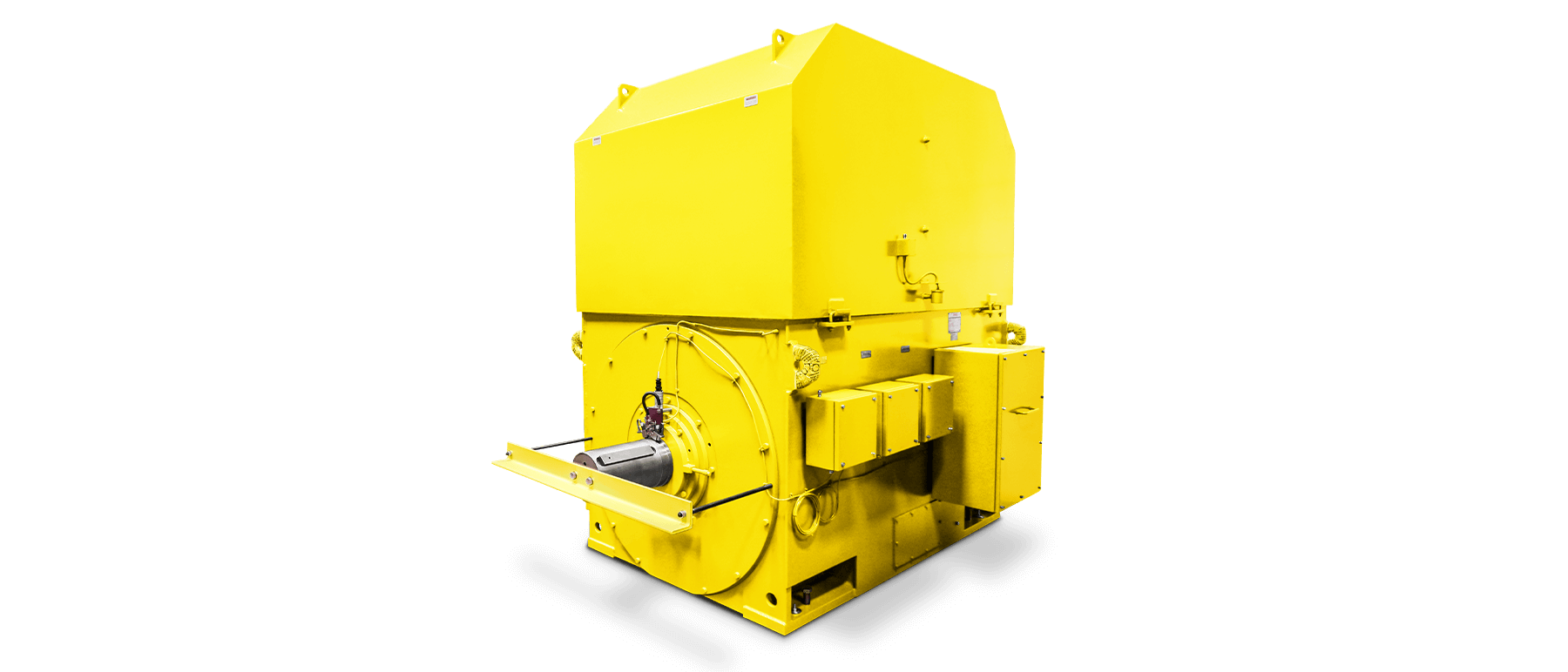

Due to the use of torsionally rigid welded steel housing, low and high voltage squirrel cage motors of cooling type IC 511 are also ideal for use in harsh conditions with load shocks and vibrations. The generously-sized roller bearings of IC 511 three-phase squirrel cage motors enable high load motor capacities, and ensure a long lifespan.

Typical applications of pipe-cooled IC 511 electric motors

User industries for IC 511 three-phase squirrel cage motors:

- Mining

- Power plants

- Cement industry

- Raw material extraction, etc.

Typical applications of IC 511 squirrel cage motors:

- Heavy-duty applications

- Conveyor belt drive

- Fan drives

- Kneader drives, etc.

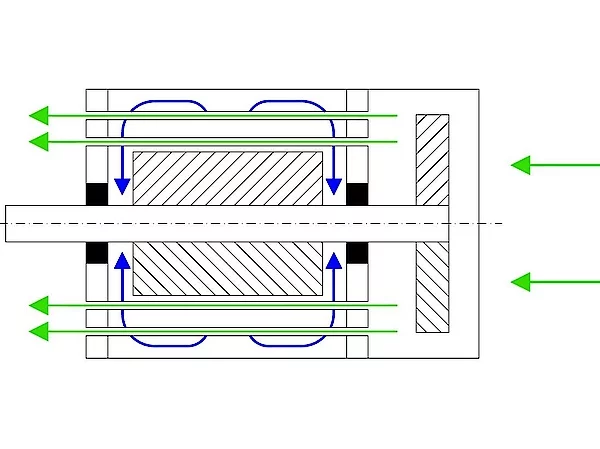

The pipe cooling principle

The pipe or tube cooling principle for IC 511 motors ensures particularly efficient, uniform cooling, because the cooling pipes are wound symmetrically around the laminated core. The primary and secondary coolants are moved by fans on the motor shaft.

The big advantage of the straight airflow through the smooth cooling pipes is the extensive self-cleaning of the pipes due to the external coolant flow. As a result, the motors are less susceptible to the blocking of the cooling system.

Are you looking for low or high voltage squirrel cage motors with a particular construction and cooling type?

MENZEL manufactures according to customer specifications.