Motors for extruders

Extruder drives up to 11000 V and 6000 kW

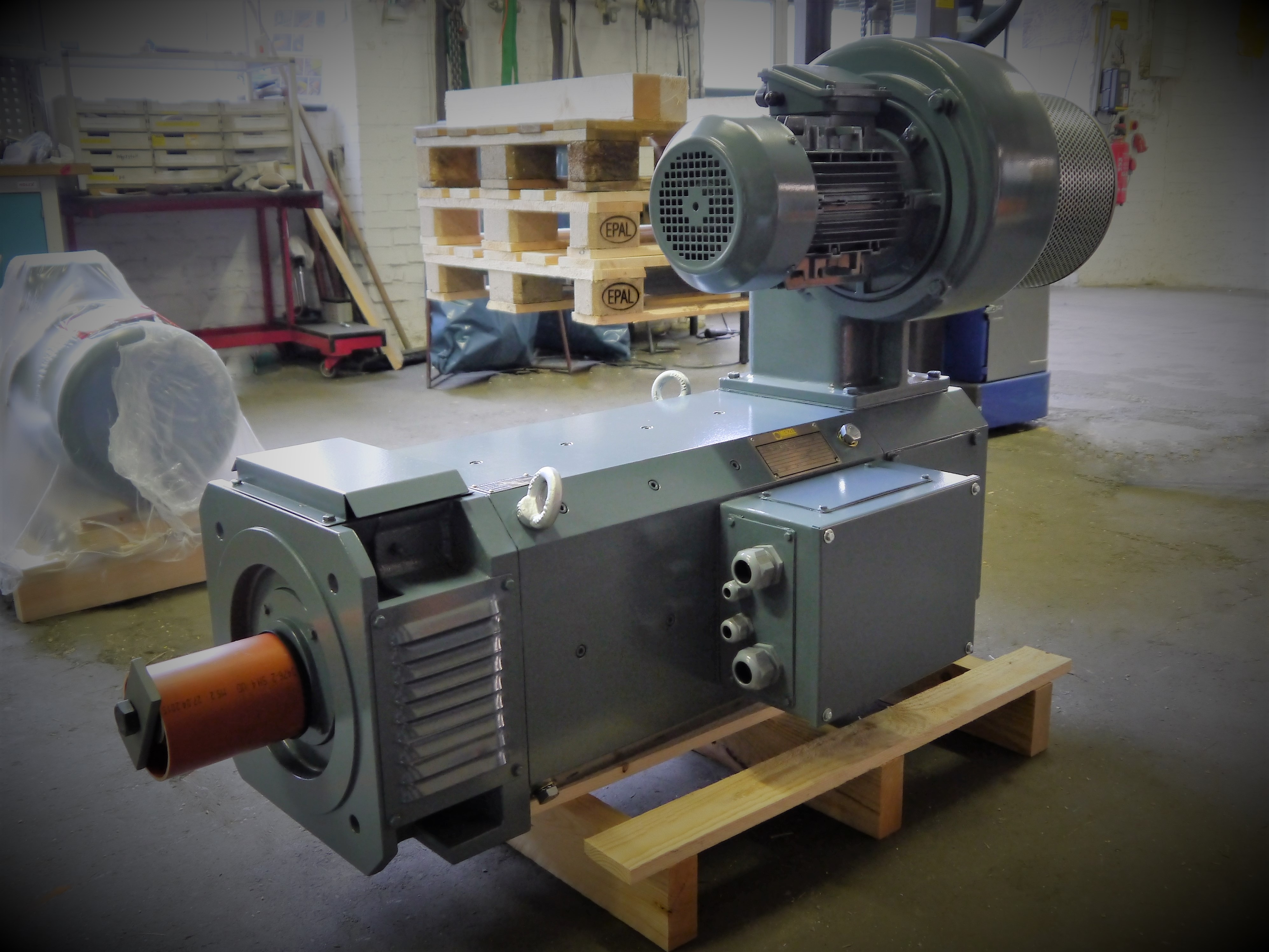

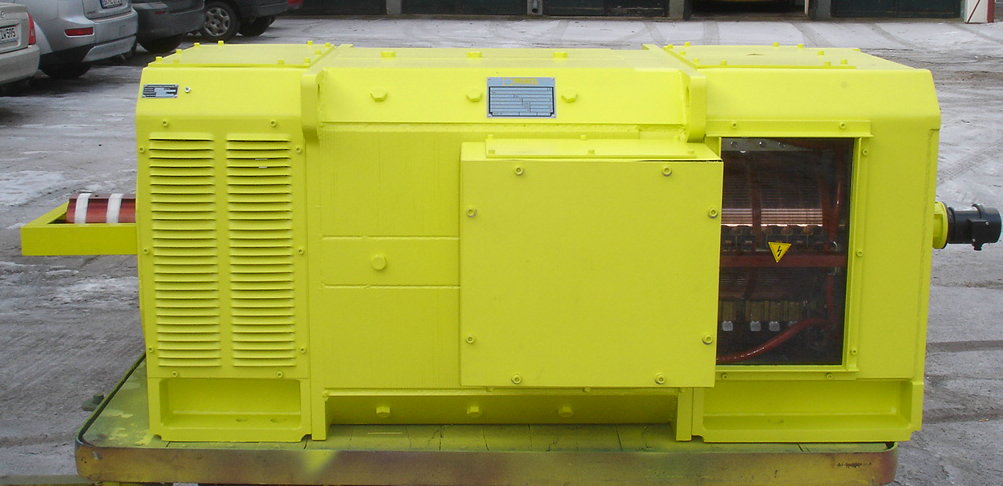

For extruder drives, MENZEL supplies both DC motors and converter-fed three-phase squirrel cage motors worldwide. A recent example of Menzel’s diversity saw a customized DC motor solution that can be used as a flexible replacement motor for two differently designed extruders.

Extruders often require a relatively large speed range with high torques at low speeds and at the same time a high overload capacity over the entire speed range. The ambient conditions for extruder drives are often relatively heavily contaminated and very warm. Our extruder motors are specially designed for both occasions and can therefore withstand these adverse environments.

Motor design for extruders

Extruder drives generally consist of an electric motor and a gear unit, the so-called extruder gear. Most usually modern extrusion systems use asynchronous or synchronous motors.

Originally, DC motors with a downstream two or three-stage spur gear, to adjust the speed, were used in extruder applications. However, energy-optimized extruders today predominantly use three-phase AC drives consisting of a standard asynchronous motor with a frequency converter. These drives are low-maintenance and they offer higher protection classes.

MENZEL offers both types of customized drive solution: application-specific DC motors and AC asynchronous motors.

Performance data of our electric motors for extruder drives

- Voltage range: from 400 V to 11000 V (11 kV)

- Power range: from approx. 100 to 6000 kW (6 MW)

- Cooling types: IC81, IC 86, IC 71, IC 416, IC 37

- Number of poles: 04 to 12 poles

- Degrees of protection: IP23, IP55

Special solutions can be implemented at any time in our own motor plant in Germany

Extruder operation and areas of application

Extruders are conveyor devices that continuously extrude viscous, hardenable plastics under very high pressure and high temperatures from a shaping nozzle (extrusion). After pressing, the plastics are cooled down so that, for example, seamless panels, pipes or profiles are created. However, extrusion can also be used to produce rolls of plastic films, sheets or tubes.

Due to the great boom in the plastics industry in the middle of the last century, the extruder has established itself as an important procedural element in the production of thermoplastics. The final products can be found in many different areas of application: packaging industry, construction industry, medical technology, automotive and aerospace industry, furniture industry and many more.

Our project engineers can support you in the correct dimensioning of your extruder motor! MENZEL specializes in the production of individually bespoke drive solutions and can flexibly work with clients to implement variations and special designs in its Berlin motor plant at any time.

Are you looking for AC or DC motors for extruders? Send us your request today!