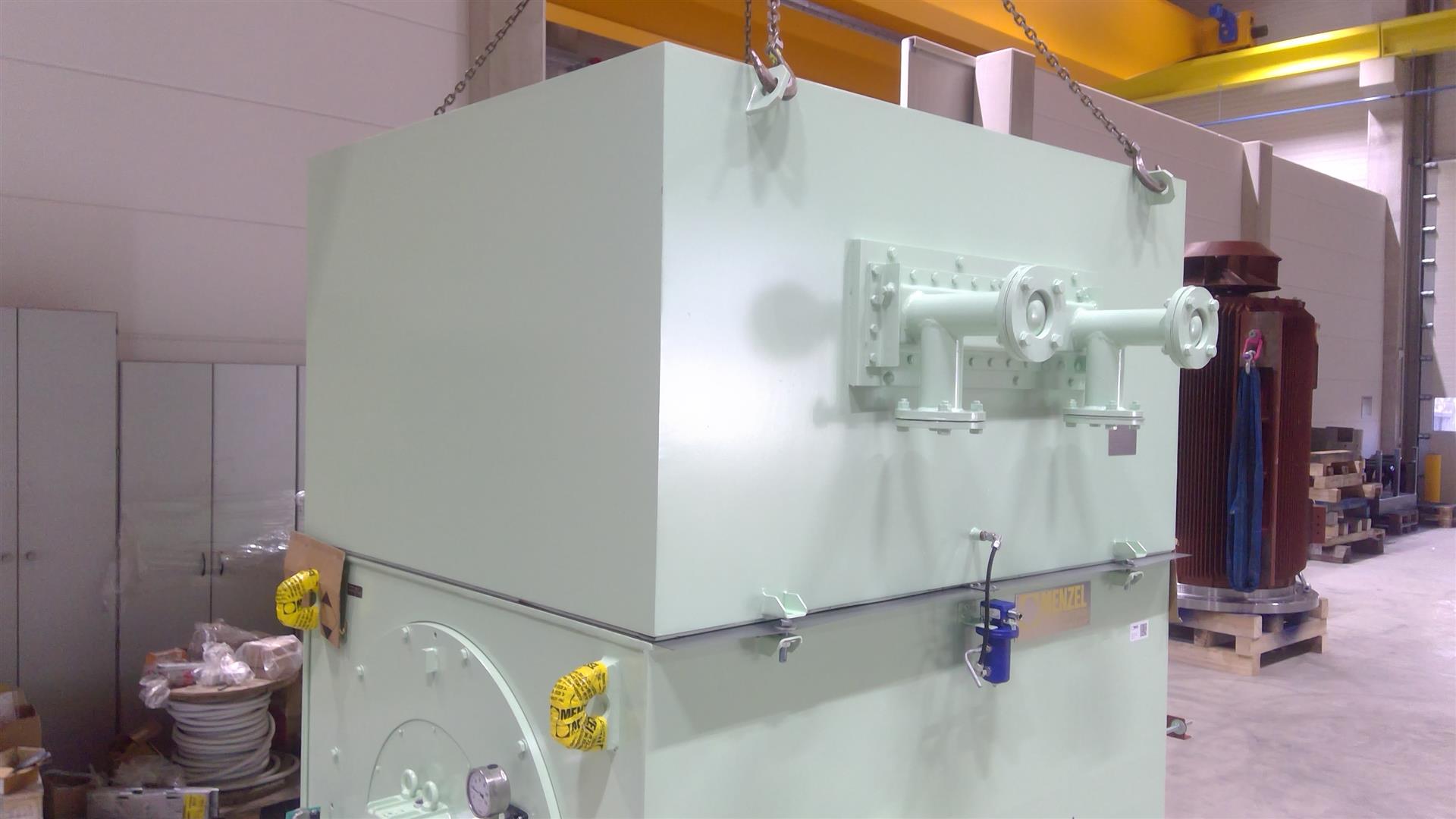

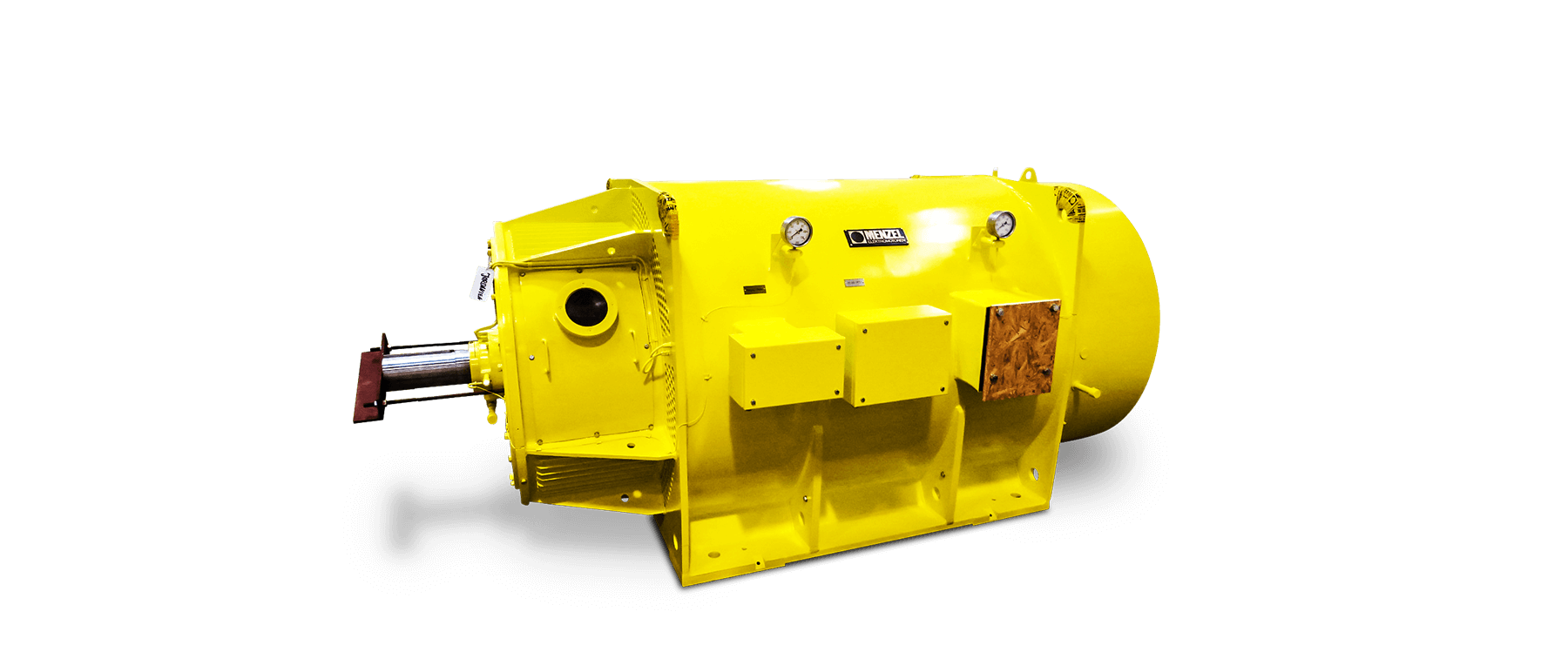

Water-cooled slip ring motors (IC 81W)

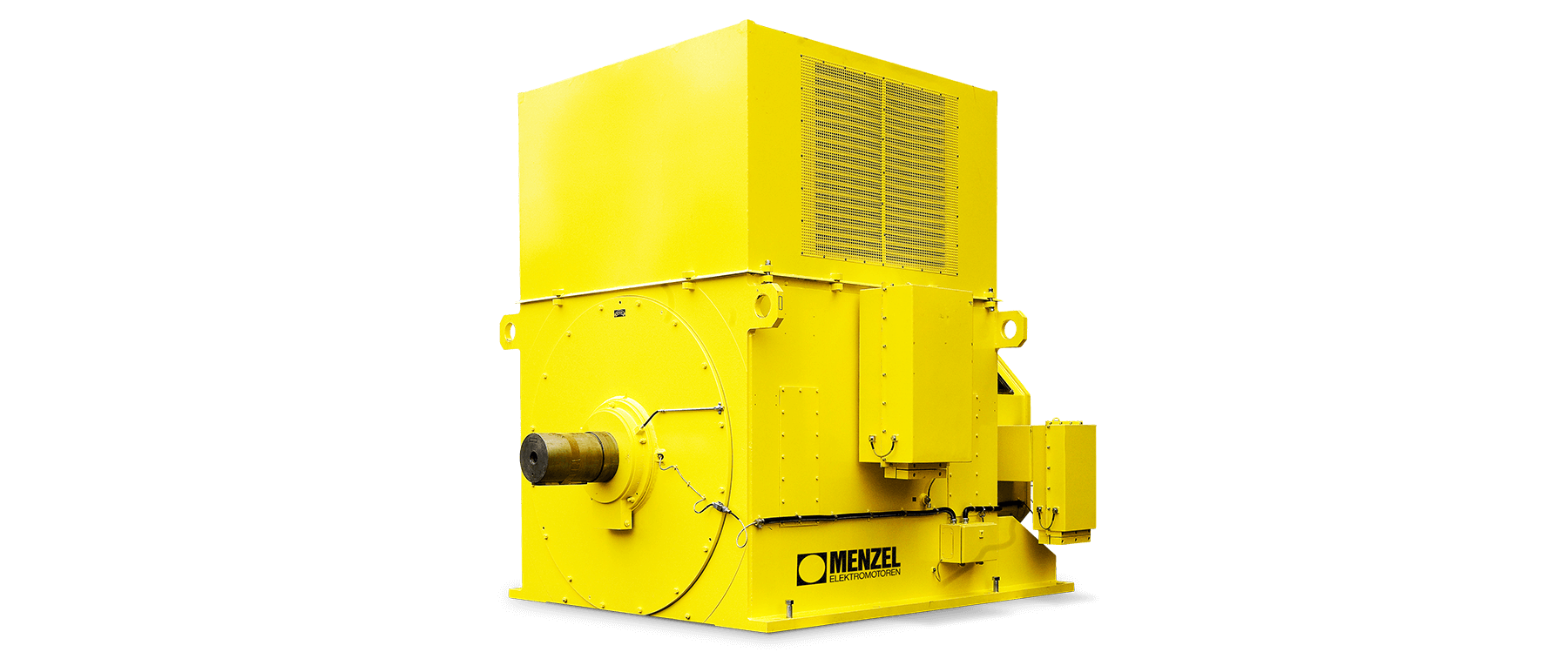

MENZEL water-cooled slip ring motors - modular structure for maximum performance

MENZEL specializes in the production of industrial motors in all protection classes and cooling types. Our slip ring motors are manufactured with a modular design for low, medium, or high voltage applications. The names of our series are based on the relevant cooling type.

The MENZEL MEBSSW series covers all water-cooled slip ring motors within the IC 81W cooling type. Alongside water-cooled slip ring motors that are part of the MEBSSW series (IC 81W), we also provide open-circuit ventilated (IC 01), surface-cooled (IC 411) or pipe-cooled (IC 511) variants or motors with air-air heat exchanger (IC 611, IC 616, and IC 666).

Standard design of water-cooled slip ring motors (IC 81W)

- Construction types: IM B3, V1

- Protection classes: IP55 and IP65

- Voltage: from 230 V to 13800 V

- Power: up to 8000 kW

- Frame Size: from 355 to 1000

- Terminal boxes: right or left, rotatable by 4 x 90°

- Motor housing: of welded steel with integrated footplates

- Thermal utilization: F/B

MENZEL water-cooled slip ring motors are manufactured precisely in line with your specific requirements. Deviances from typical standard designs can be realized at any time if required.

Available voltage ratings of water-cooled slip ring motors (IC 81W)

Special voltages and deviating voltage tolerances can be delivered at any time on request.

Nominal voltage at 50 Hz

- Low voltage: 220 V, 380 V, 400 V, 500 V, 690 V

- Medium and high voltage: 3.000 V, 3.300 V, 5.000 V, 5.500 V/ 6.000 V, 6.300 V, 6.600 V, 10.000 V, 10.500 V, 11.000 V

Nominal voltage at 60 Hz

- Low voltage: 380 V, 400 V, 440 V, 480 V, 500 V, 525 V, 575 V, 690 V

- Medium and high voltage: 2.300 V, 4.160 V, 6.000 V, 6.600 V, 7.200 V, 11.000 V, 13.200 V, 13.800 V

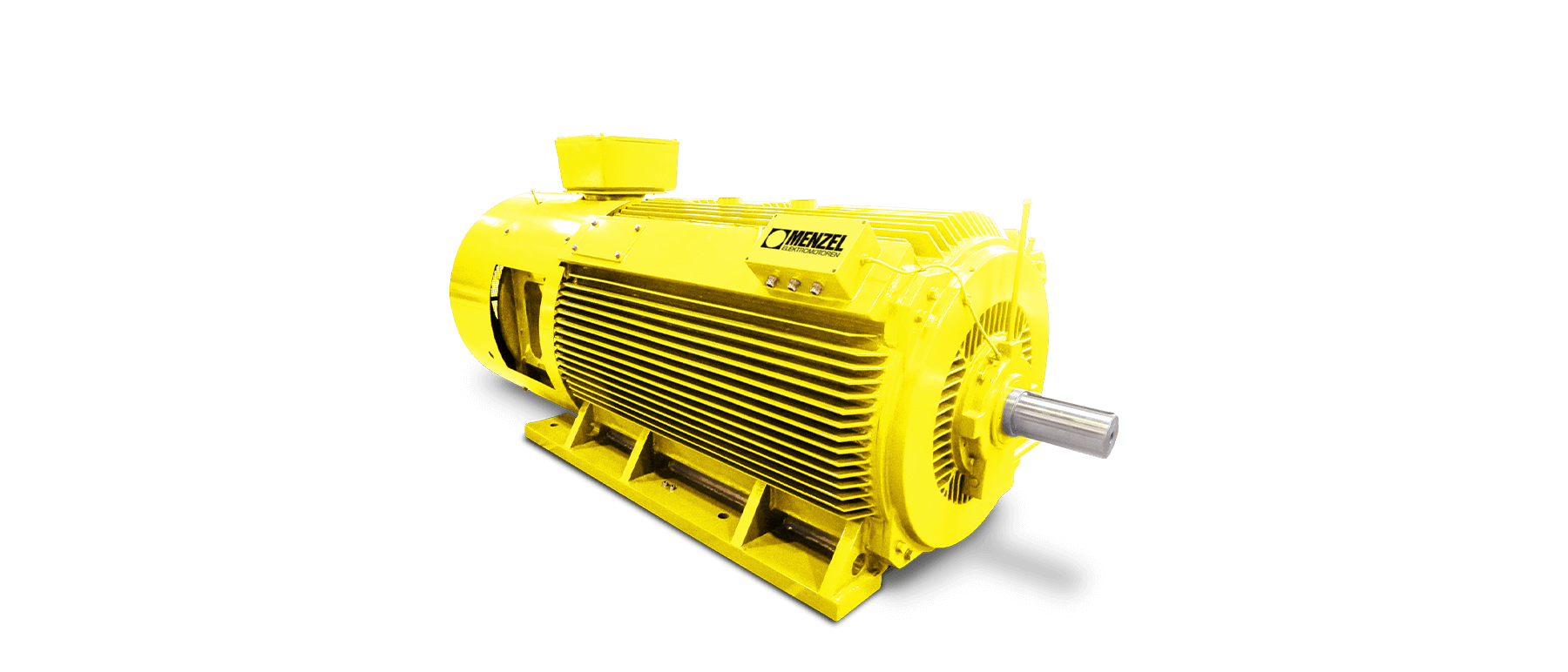

The advantages of MENZEL modular slip ring motors

High level of efficiency and extremely low operating costs

Compact design, small size, and low weight

Reliable and durable bearing design

Low vibration and low maintenance costs

Reliability and long product life

High load-bearing capacity

Low noise emissions

Special designs in accordance with customer requirements

Air-to-water cooled electric motors (IC 81W) - characteristics

In comparison to air-air cooling, air-to-water cooled electric motors have the advantage that the machines can be built more compactly, but with the same power rating whilst having lower mass and also lower noise levels. In addition, water cooling of electric motors is very efficient and enables high performance or torque density.

The inner cooling circuit is separated from the environment by seals, pursuant to the motor protection class. This is a further advantage as it means motors are best suited for use in industrial plants where the ambient air is not sufficiently clean for cooling purposes. At the same time, the use of water-cooled electric motors is beneficial where machines have to be protected from external atmospheric effects or where waste heat should be removed.

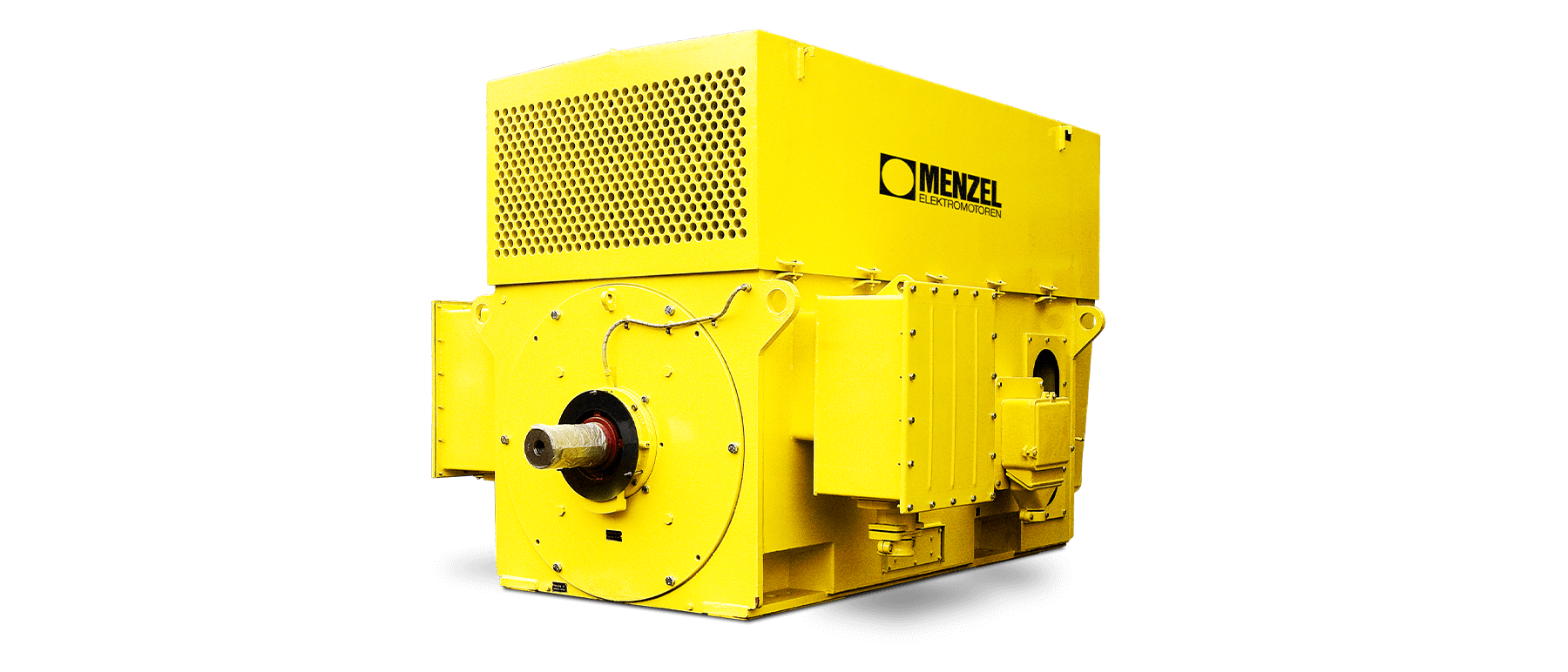

Typical applications of water-cooled slip ring motors

Typical user industries:

- Process industry

- Paper industry

- Plastic industry

- Plastics industry

- Water and wastewater management

- Steel industry

Slip ring motors in the IC 81W cooling class are suitable as:

- Refiner drives

- Shredder drive

- Compressor and compactor drives

- Fan drives

- Pump drive

- Kneader drives

The air-water cooling principle (IC 81W)

The air-water cooling principle in line with IC 81W functions as a cooling circuit where the primary coolant (air) flows into a closed internal circuit, and the heat is transferred via a mounted fan cover, known as an air-to-water heat exchanger, to the secondary coolant (water).

The heat generated in the motor is led into the air-water heat exchanger via an internal fan. The air-water heat exchanger cools the internal circuit air flowing through it to the required temperature again. The choice of material for cooling pipes and water tanks in the air-water heat exchanger depends on the quality of the cooling water or your individual specifications.

Special designs that deviate, such as with regard to speed control, forced ventilation, or pipe connection with motors that run particularly slowly, can be delivered as a special design on request at any time.

The air-water cooling principle can be found with MENZEL electric motors, both with the design as slip ring rotor as well as a squirrel cage rotor.

Are you looking for water-cooled slip ring motors for your industrial plant? Send us your inquiry! We manufacture slip ring motors in the most varied cooling and protection classes.