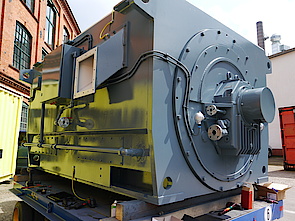

Increased safety motors mounted at record speed, in record size - when an turbo compressor motor failed in an Oil and Gas company in Algeria, MENZEL was once again able to keep its promise to deliver a replacement within only a few days.

The new increased safety squirrel-cage motor with a shaft height of 800 mm weighs all together over 33 t. MENZEL was the only motor manufacturer able to provide a replacement motor of this size at short notice. Drawing on modular stock components, we were able to assemble a suitable non-sparking motor and even found an efficient solution when it turned out, during commissioning, that higher starting torques than projected were needed..

Explosion-proof motors of this scale are not available off the shelf but are more usually built to order. Manufacturing a completely new motor of this size takes six months at best - the loss in revenue would have been considerable.

Increased safety motors directly from stock

Due to our huge inventory of AC motors and DC motors, MENZEL is extremely flexible and can quickly provide drive solutions for all common industrial applications - even in explosion-proof versions. We keep a large number of prefabricated components in stock in our warehouses in Berlin, Germany and are able to build large industrial motors to customers' exact specifications at short notice.

The oil producer in Algeria had suffered two stalled compressors because overload during startup damaged one motor. The compressors are used for gas injection, to maintain the reservoir pressure. As a result of the failure, the production rate dropped dramatically. Our team worked on the project under high pressure, working through weekends to quickly set the gas compressors in motion again.

Explosion-proof motors for ATEX Zone 2

The motor's intended purpose in the oil industry required an explosion-proof design. It features the explosion protection type non-sparking and is labeled II3G Ex nA IIC T3 Gc for use in ATEX zone 2 gas atmospheres. The motor's protection type Ex nA corresponds to the newly introduced Ex ec. Both labels are still awarded.

An additional requirement of the customer was that the new ATEX motor is pre-purged with nitrogen according to IEC/EN 60079 before starting. For this we installed flushing connections and an additional switch box and provided suitable gaskets. Initial flushing with an inert gas ensures that there is no risk of ignition even at very high startup temperatures.

Ex ec and Ex tc motors for Zone 2 and 22

All our Ex ec motors and Ex tc motors fulfill the current European ATEX guidelines. MENZEL offers you a wide selection of low, medium and high voltage motors for potentially gas and dust explosive industrial areas.

Our explosion-proof three-phase motors boast particularly robust and high-quality motor construction. They have an optimal level of efficiency and are typically used in compressors, gas and steam turbines, ventilators, pumps, mixers and agitators:

Our production range of motors for Zone 2 and 22

- Power range: from 55 kW to approx. 5000 kW

- Voltage: up to 13.8 kV (for 50 and 60 Hz)

- Common construction types: IM B3, IM B5, IM V1, IM B35

- All standard sizes, protection classes and cooling types

Customized motors and drive solutions

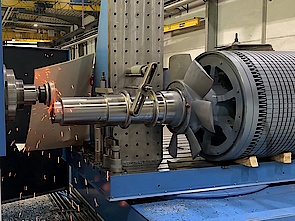

The stocked squirrel cage motor had to be customized for its use in the oil industry. The direction of rotation had to be changed, which also necessitated a speedy replacement of the fan blades. At the same time, the shaft end was shortened, drilled to the right diameter, and fitted with new bore holes. Eventually, the rotor was balanced.

Our welding shop manufactured a support ring for the customer's coupling guards, a job which required maximum dimensional accuracy to ensure an oil- and gas-tight fit. The cooling type was changed from air-to-water heat exchanger to air-to-air cooling (IC 616). And the MENZEL welders also built an intermediate frame to guide the airflow in a closed ventilation circuit.

The on-stock stator had a rated power of 14 MW – this was reduced to 7.9 MW due to the changed IC 616 cooling type, reduced voltage, and explosion-protection requirements. For one thing, air-to-air cooling is not as effective as air-to-water cooling. For another, Menzel lowered the motor voltage to 5500 V for this application. The motor power is now a little higher than necessary; however the new motor is also more efficient than the old one.

Another important customer specification was that the replacement motor must be mounted on the existing foundation without any changes to the construction. Accordingly, Menzel welded another frame of the right height and with bore holes to fit the installation site.

Technical data of the increased safety EX ec motor

- Type: Squirrel cage motor II3G Ex nA IIC T3 Gc

- Application: Turbo compressor

- Norm: IEC / EN60034-1

- Rated power: 7900 kW

- Voltage: 5500 V

- Frequency: 50 Hz

- Poles: 4 poles

- Rated speed: 1490 min-1

- Mounting: IM B3

- Protection: IP 55

- Cooling: IC 616

- Weight: 33100 kg

Menzel produces customer-specific drive solutions and special motor designs in the power range up to 25000 kW. On request, we can also rebuild old Siemens or ABB or any other motors that are no longer available on the market.

Commissioning and service on site

MENZEL also offers its customers around the world motor commissioning, maintenance and service. Ready access to an experienced commissioning engineer, who can diagnose problems and offer efficient solutions, proved to be fundamental in this case in order to get the application back on track quickly.

When our team discovered during commissioning that the actual counter torque is much higher (The customer had not provided sufficient information about the driven compressor. In particular, there was no authoritative specification of the counter torque.) we designed a pragmatic switching solution. In this new configuration, the application has been successfully commissioned and is running reliably.

The customer is fully satisfied with our services. They have already placed a follow-up order for a spare motor so that, in the event of another motor failure in this application, it can quickly be replaced.

Are you also looking for large increased safety motors? Send us your request today!