Reconditioning of electric motors - the cost-effective alternative

With the modernization and reconditioning of high-voltage, low-voltage, and direct current electric motors, MENZEL offers an alternative to a newly constructed motor.

If maintenance and repair are no longer sufficient and a newly constructed electric motor is too costly, MENZEL can provide a cost-effective alternative in the form of a high-quality reconditioned motor. The availability of your industrial plant can be quickly and flexibly secured for the long term with an overhauled motor. Through reconditioning older drives, we can also modernize them and improve their efficiency.

As a manufacturer of large electric motors for industrial applications, we're ideally placed to judge what's necessary during reconditioning. Thanks to many years of experience, our MENZEL technicians and engineers can precisely assess which components need to be replaced or reconditioned and which can be reused. This allows us to inject new life into old motors.

Naturally, you get the same full MENZEL guarantee service on all three-phase and direct current motors reconditioned by us.

Fast and flexible reconditioning of electric motors

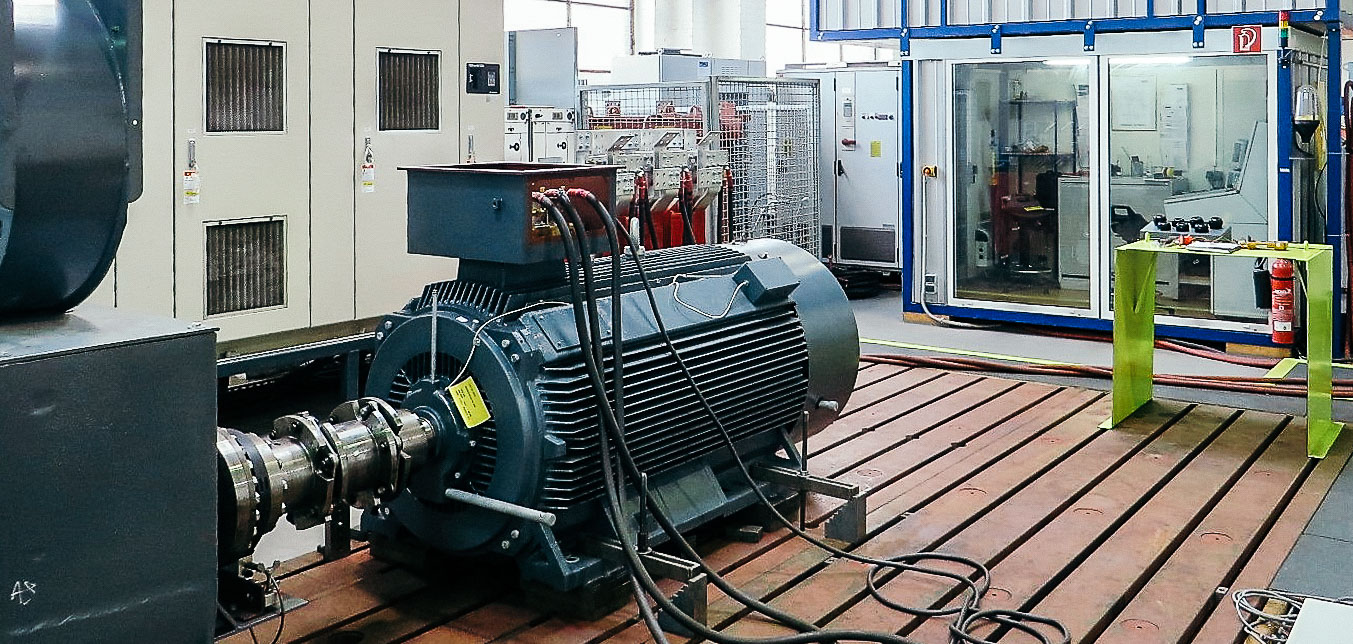

At our test bay - fitted with the latest measurement equipment - we can carry out all required motor tests before, during, and after the reconditioning process. Our test bay engineers can make precise diagnoses and ensure our high quality standards in the production and overhaul of three-phase and direct current drives.

A further plus point: All work steps that are needed for the reconditioning or overhaul of an electric motor including disassembly, cleaning, drying, balancing and so on are carried out in close proximity at our own motor factory in Berlin. This saves time and money. With extensive modern production facilities and a high vertical range of manufacture, we are able to carry out all required work steps quickly and flexibly. The economic efficiency of a motor overhaul is always at the forefront of our minds.

MENZEL services for the reconditioning of a motor

The reconditioning or overhaul of motors in accordance with our quality management system includes the following services among others:

- Complete disassembly of the motor

- Check of all electrical and mechanical components

- High-pressure cleaning and chemical cleaning of all parts

- Drying in air circulated furnace

- Re-impregnation of winding (if required)

- Re-winding of stator and rotor (if required)

- Check of winding insulation

- Balancing check and balancing of rotor

- Re-turning of slip rings/collector

- Renewal of carbon brushes

- Check of all clearances

- Check and cleaning of motor connection terminals

- Complete overhaul of bearings, bearing calculation, and dimensioning

- Assembly

- Motor test as per EN 60034 and VDE regulations at our own test facility

- Creation of test report

- Painting as required

All work is carried out at our own fully equipped factory in Germany.

Advantages of professional motor reconditioning by MENZEL

Fast and flexible reconditioning at our own motor factory

Many years of experience with all motor models

Enhancement of electric motors through retrofit

Increase in efficiency level and energy efficiency

Drives overhauled in our factory available immediately, directly from stock

Fast, cost-effective solutions

Professional advice directly from the manufacturer