The Challenge: One had to fit all - IM V1 and IM V3, 1000 kW to 1400 kW

The customer, Nordzucker AG, operates several sugar beet processing plants where drying the beet chips and pulp after sugar extraction is a critical step involving heavy-duty industrial motors driving complex drying systems. Procuring and maintaining distinct reserve motors for each facility posed challenges. The customer wanted a spare motor that can basically employ the three-phase squirrel cage motor in any of its plants in Sweden and Germany.

Nevertheless, each plant’s equipment, ranging from drum dryers to low-temperature band dryers or hybrids of both, demanded individual motors with slightly differing mechanical interfaces and power requirements. A possible spare motor needed to be adaptable to different mounting orientations – both vertical flange mounting in standing (IM V1) and hanging (IM V3) positions and withstand harsh industrial environmental conditions. The demanding power range of 1000 kW to 1400 kW with specific speed and protection class further complicated the quest for a standardized, multi-factory usable motor.

The Menzel Solution

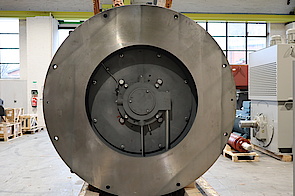

Menzel Elektromotoren responded by developing a custom-configured three-phase squirrel cage motor engineered explicitly to serve as a universal backup motor adaptable for all four sugar plants. By leveraging the modular MEBKSL motor series, Menzel optimized the motor design for flexibility without compromising on reliability or performance. The motor’s construction (IM 3011), allowing both standing flange mounting (IM V1) and hanging flange mounting (IM V3), directly addresses the customer’s need to deploy the same motor in different mechanical configurations.

Recognizing the unique installation constraints, Menzel incorporated a bespoke adapter flange system manufactured in-house that enables additional foot mounting compatibility at one of the plants. The motor’s robust engineering includes a cooling concept compliant with IC 616, ensuring efficient heat dissipation under continuous load, paired with an IP55 ingress protection rating in harsh industrial environments.

Prior to delivery, the motor underwent rigorous factory acceptance testing, including no-load operation at rated speed and vibration measurement, with the customer’s technical team present at Menzel’s Berlin facility. This close collaboration assured the motor’s compliance with demanding operational standards and provided Nordzucker AG with confidence in the motor’s readiness for deployment as a versatile standby solution.

Motor Specifications

- Motor Design: Three-phase squirrel cage rotor

- Motor Type: MEBKSL560-08

- Power Output: 1,400 kW

- Rated Voltage: 690 V

- Frequency: 50 Hz

- Rated Speed: 742 rpm

- Pole Number: 8

- Mounting: Vertical flange mounting (IM 3011 / IM V1 standing, IM V3 hanging)

- Protection Class: IP55

- Cooling Class: IC 616

- Weight: 9000 kg

Our electric motor expertise, your advantage

This project clearly illustrates how Menzel’s in-depth engineering expertise translates into direct operational flexibility and cost efficiency for you. By delivering a single, modular motor configurable for various mounting orientations, we eliminate the need for multiple spare motors and reduce your spare parts inventory complexity. Menzel’s tailored modular approach means you benefit from optimized manufacturing costs without compromising on high standards of power output, protection, and cooling.

If you require a joker motor solution that combines universal compatibility, robust performance, and engineered adaptability for multiple installations across your operations, this project serves as a model for what Menzel Elektromotoren can deliver for you.

Speak directly with our engineers to explore how we can design a custom motor for you or send us a short enquiry. We will get back to you promtly.

Enquiryform