Performance data of the replacement motor

- MENZEL motor type: slip ring motor MEBSSL800-06

- Motor standard: IEC / EN 60034-1

- Rated power: 6750 kW

- Rated voltage: 6600 V (9052 HP)

- Rated frequency: 50 Hz

- Number of poles: 6 poles

- Rated speed: 992 min-1

- Type of construction: IM B3

- Frame size: 800

- Protection class: IP 55

- Cooling type: IC 611

- Weight: 29.400 kg

Professional logistical management ensures fast delivery

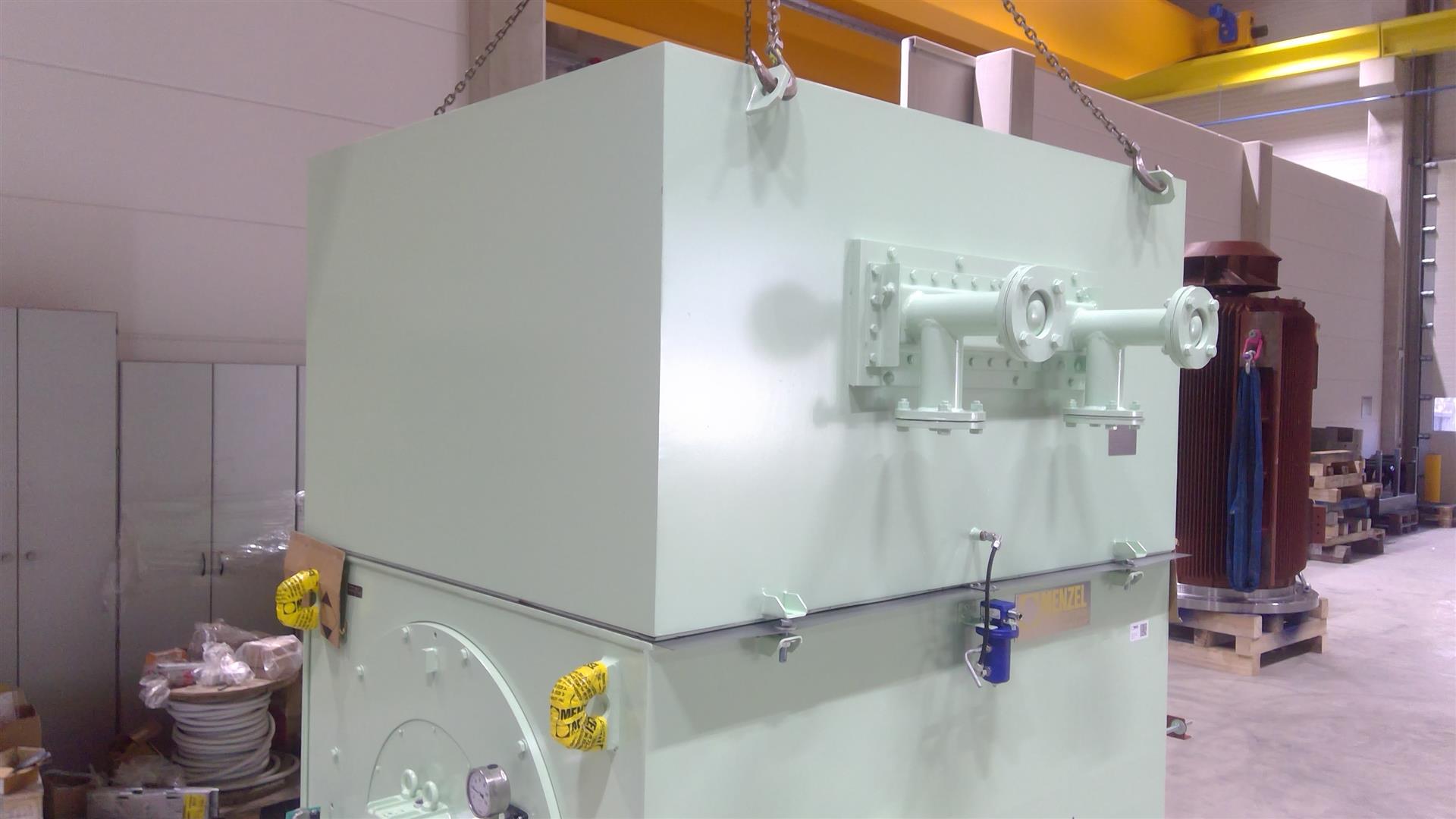

Before the motor colossus weighing almost 30 tons set off on its long truck journey to its destination, it was thoroughly tested in our in-house test facility. It was then partially disassembled and securely packed for its journey to the open pit mine.

Particularly when things have to be done very quickly and every day counts between the first electric motor inquiry and final commissioning, the transport procedures also have to run smoothly. Our experienced MENZEL logistics team takes care of the often very complicated document processing as well as the shipment preparation in close coordination with our customers and the responsible authorities - regardless of whether the electric motor arrives at its final installation site by truck, ship, or airplane.

Extremely robust electric motors for the mining industry

MENZEL is a manufacturer and supplier especially for large, robust electric motors. Especially in the mining industry, such motors are in demand that can withstand extremely harsh operating conditions. A mill drive, as in the case of this iron ore mine, is exposed above all to a lot of dust and at the same time to strong vibrations. Electric motors for mine applications must be able to withstand this.

MENZEL motors are particularly robust due to their design and are therefore used in a wide variety of heavy duty industries. In addition to mining companies, our worldwide customer base also includes end customers and suppliers in the cement, paper, water and steel industries.

MENZEL supplies mill motors for iron ore mines

After their extraction, iron ores are often processed directly at the mining site. In the process, they are separated from most of the gangue. During the processing of the iron ore, the raw material is first crushed in several steps. Cone crushers or jaw crushers as well as mills such as ball mills are used in the crushing process. The motors for these mills and crushers are supplied by MENZEL.

If you go by the throughput of ore in 2022, the Escondida mine in Chile is the world's largest iron ore mine. It is in the Atacama Desert. The main raw material there is copper, but gold and silver are also contained in the rock and are mined.

MENZEL offers rebuilding of all motor types - fast and reliable

MENZEL Elektromotoren can identically rebuild existing motors of all types and power classes - from 100 kW crane motors to mill motors in the megawatt range. Often a specific electric motor is produced for a specific application. When this motor needs to be replaced, a virtually identical motor is required. We can exactly replicate motors so that the new motors are 100% matched to your equipment.

We can custom replace virtually any electric motor with a replica. We have done this thousands of times in our 100-year company history. So, if you are looking for three-phase asynchronous motors or DC motors from manufacturers such as Siemens or ABB that are no longer available - even special and custom designs - we are the right partner for you.

By using modern components, we can also significantly increase the efficiency of your plant. Just ask our engineers - ideally you have the motor data and dimensional drawings of the motor to be replaced directly at hand - and off you go!

Send us your enquiry today!

Enquiry form