Tailored solutions for the perfect fit

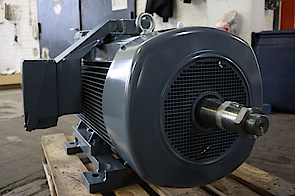

Standard motors often do not meet the specific requirements for foot spacing, shaft dimensions, or shaft heights. Modifications to the cranes themselves are not feasible due to technical approvals, safety inspections, and operational safety requirements. MENZEL therefore manufactured custom foot adapters to ensure an exact mechanical fit. The motors feature two shaft ends:

- On the drive side, the gearbox transmitting motion to the rope drum is connected.

- On the non-drive side, the brake is attached to ensure safe stopping of the hoist.

In addition, the stator and rotor connections were combined in a single junction box, symmetrically positioned. This box can be rotated in the direction of the supply cables, allowing the motors to be installed easily even in confined spaces or in different installation positions.

Technical Highlights of the MEBSGR crane motors

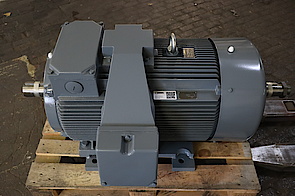

The delivered motors come from the energy-efficient, low-noise MEBSGR series, specially designed for hoist applications. Key specifications include:

- Motor type: Three-phase slip ring motor MEBSGR250M-04

- Rated power: 63 kW

- Rated voltage: 550 V

- Rated frequency: 50 Hz

- Number of poles: 6

- Rated speed: 980 min-1

- Type of construction: IM 1002 (IM B3) with two shaft ends

- Protection class: IP 54

- Cooling type: IC 411

- Weight: 665 kg

- Special features: high starting torque at low starting currents, overload-capable, custom foot adapters, two shaft ends, flexible junction box

Thanks to these technical features, the motors are ideal for recurrent start-stop operation while maintaining low inrush currents, reducing operating costs and extending the service life of the motors.

Reliable motor technology for crane and hoist applications

The precise replication of all mechanical and electrical mounting dimensions allows direct installation on existing cranes without modifications to the foundations or crane structure. For the operator, this provides:

- Minimal downtime when replacing older motors

- Maximum operational safety through precisely matched mechanical and electrical components

- Flexible deployment in different installation positions or confined spaces

- Long-term reliability thanks to high-quality, overload-capable motors

As an experienced manufacturer, Menzel Elektromotoren places great value on customer-oriented solutions. Special requirements, which may be considered too complex, can be implemented flexibly. This enabled the hoist motors to be perfectly adapted to the existing crane conditions, ensuring efficient, safe, and trouble-free operation.

Contact our engineers!

Planning to replace older motors or need a customized solution for your crane systems? We develop individual motor solutions for maximum operational safety, flexibility, and efficiency.