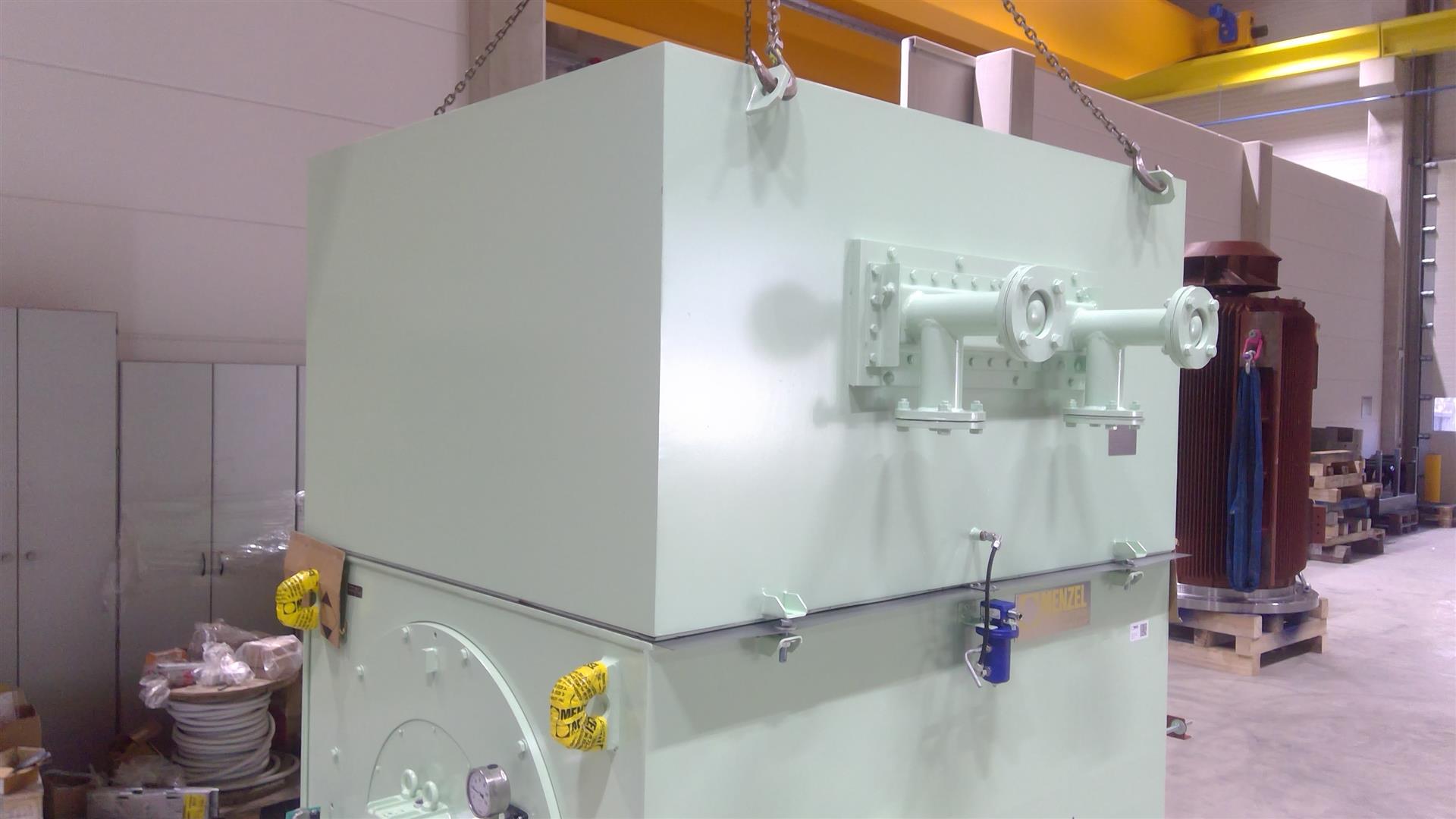

4-pole squirrel cage motors for driving slurry pumps

MENZEL supplied five identical pump drives with 355kW power, 6000 V nominal voltage and a nominal speed of 1490 min-¹ for a globally active company, offering end-to-end solutions and services for minerals processing and mining industries.

The five motors are used to drive slurry pumps. Slurry handling plays a crucial role in mineral processing in the mining industry. MENZEL supplies the suitable 4-pole squirrel cage motors - whether as a quick replacement motor for a failed motor or in small series for entire pump systems.

Performance data of the slurry pump drives

- Menzel motor type: MEBKGR400-04

- Application: Slurry pumps for minerals processing

- Motor standard: IEC / EN 60034-1

- Rated power: 355 kW

- Rated voltage: 6000 V (6 kV)

- Rated frequency: 50 Hz

- Number of poles: 4 poles

- Rated speed: 1490 min-1

- Type of construction: IM B3

- Frame size / Shaft height: 400 mm

- Protection class: IP 55

- Cooling type: IC 611 (CACA - air-to-air cooling)

- Weight: 3170 kg

Slurry handling in mineral processing

Slurry handling is a key process of all wet processes in mineral processing in mining. The term "slurry pump" is used to describe various types of heavy centrifugal pumps used for pumping liquids containing solid particles. They pump slurry water that is mixed with clay, silts, mud, or sand.

Slurry pumps are indirectly driven by an electric motor with belt drive or gear transmission, or directly coupled, i.e. pump and motor form one unit. Squirrel cage motors are used. In the case of belt drives, most commonly 4-pole motors are used.

A distinction is made between dry, semi-dry and wet installation of slurry pumps. "Dry installation" - as in this case - means that the motor and shaft bearings are outside the slurry. They do not come into contact with the process fluids.

Electric motors with high efficiencies

Electric motors from MENZEL achieve their high efficiencies through the use of high-quality materials, such as low-loss electrical laminations, optimized design features and high-precision manufacturing. We have almost 100 years of experience in building special motors for a wide range of industrial sectors and supply companies worldwide with flexible drive solutions - often at short notice, for example, to avert serious production downtimes or restrictions.

Are you looking for pump drives or other industrial motors? Send us your inquiry!

Enquiry form