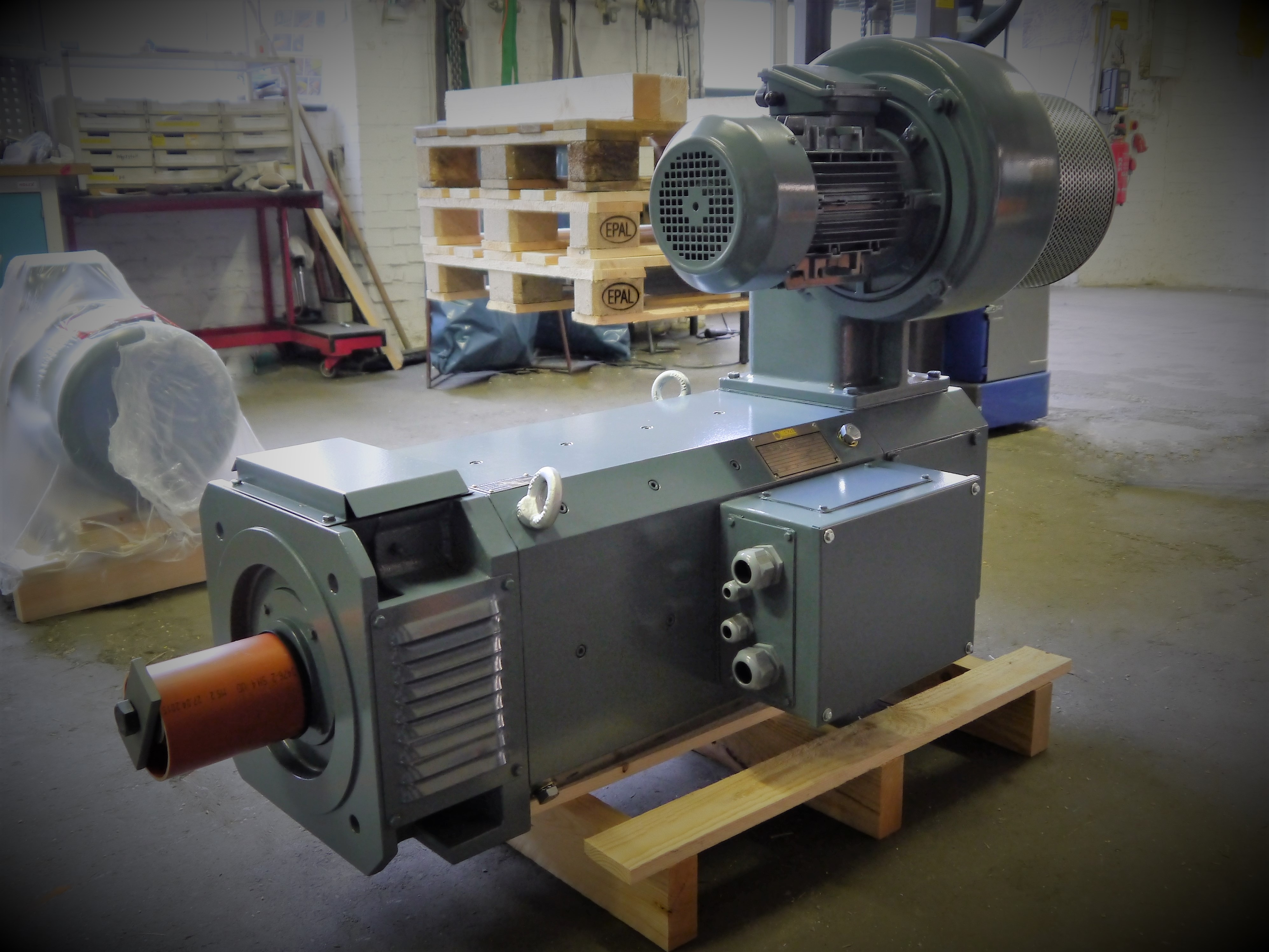

DC motor as replacement motor for underground mine in Australia

Recently, MENZEL supplied a replacement motor to an underground mine in Australia.

An old DC motor of the Leroy-Somer brand, which is no longer available on the market, was to be replaced. MENZEL still has in its production program, the ability to directly replicate obsolete electric motors, including DC motors, after consultation with the customer, we were able to assist the mine operator down under with a suitable replacement.

In addition to our DC motors, we also offer a wide range of suitable accessories and monitoring devices, such as tacho generators or encoders. In the case of the Australian mining operator, an 800 kW DC motor with attached encoder was requested.

Technical data of the DC motor

- Type: MEBGVF 450 XS DC motor with mounted encoder

- Motor application: Double Drum Winder

- Rated power: 800 kW

- Rated voltage: 650 V

- Rated speed: 1435 min-1

- Type of construction: IM B3

- Protection class: IP 23

- Cooling type: IC 06

- Weight: 4080 kg

The task of a DC Motor to drive a mine hoist system

The DC motor will drive a hoisting system in an underground mine. Hoisting machines in mines are used to transport material baskets with rock or overburden from the various underground mining levels to the surface. The challenge was, that such a pit cage runs a special load cycle: The load cycle lasts approximately 360 seconds. During this time, the DC motor runs up in one direction - runs down again until it stops - and then runs up again in the other direction. The armature current varies greatly during this time.

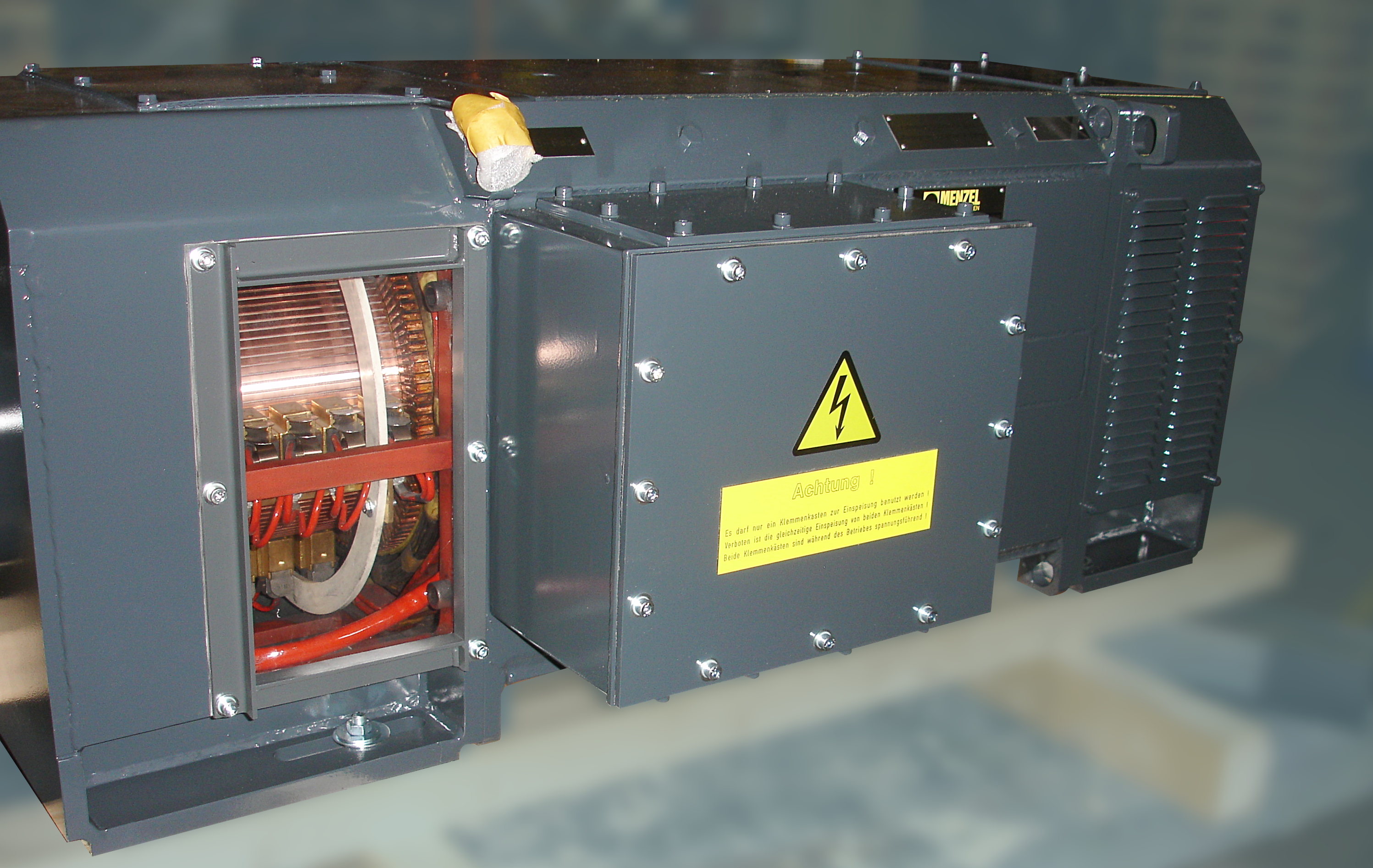

While the pit cage is descending, the electric motor brakes almost entirely electrically. During loading, it stands still. Then the fully loaded basket moves up again, which means a lot of electrical work. To unload, it again stands still before the process starts all over again. This is not an easy task for a DC motor, because for the carbon brushes a constant current and a constant temperature are the ideal working condition, which is not the case with such a duty cycle.

Hence it required a very good tuning of the DC - motor (for the full load and partial load ranges) with special attention to the brush apparatus and the carbon brush design.

Why did the customer again decide on a DC motor as a replacement motor?

The truth is that the construction of a DC motor is more complex and thus in many cases more cost-intensive, especially because of the commutator, the brushes, and the armature windings. Maintenance of the brush/commutator assembly of DC motors is also more costly in comparison.

Nevertheless, the customer opted for a DC motor because he was convinced by decades of reliability of the existing DC motor. Furthermore, the use of a converter to supply the requested DC motor also results in very good adaptability to the existing and previously described load cycles.

The special challenges for DC motors in mining

Any DC motor used as a hoisting drive in a mine must be capable of both forward and reverse operation and must be able to produce maximum output torque at all speeds, from standstill to full speed.

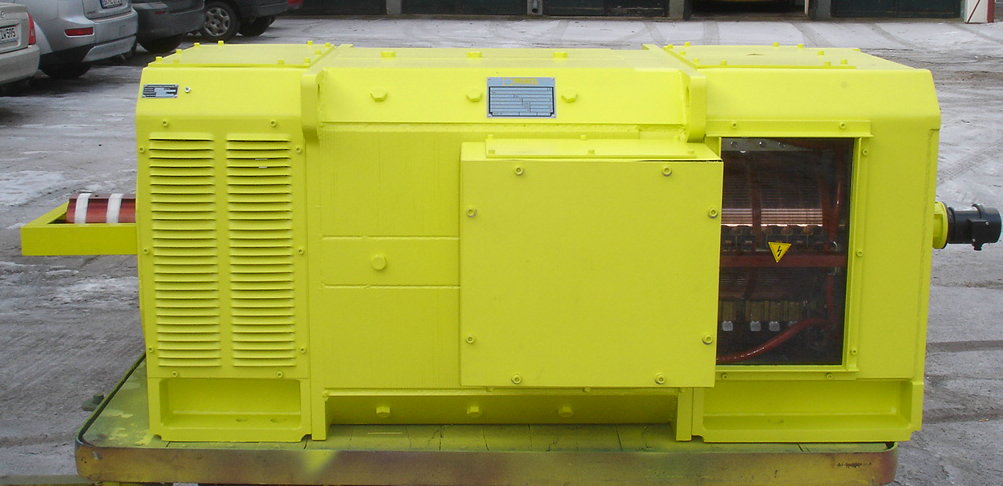

At the same time, motors for underground hoisting equipment must be able to withstand the specific harsh operating conditions. In mining, there are sometimes high temperature fluctuations, a lot of dust, high humidity, and vibrations.

In this case of the replacement motor for the underground mine in Australia, the MENZEL engineers chose a so-called short design (very short length of the motor body). The bearing shields were reinforced, and the particularly robust rotary encoder favored by the customer was mounted. The filter material used for the radial forced draft fan is a special nonwoven made of synthetic fibers, which tolerate high temperature and humidity very well. The clean air side of the filter material has a progressive structure, so that long service lives are achieved.

Electric motors for hoists and winding machines

In underground mining, hoists or winding machines are used to raise and lower conveyances within the mine shaft. There are three main types of hoists used in mining: Drum hoists, friction or Koepe hoists, and so-called Blair hoists.

Until the beginning of the 20th century, electric motors were used only occasionally, and then only to drive small hoisting machines. Today's hoists and winding systems are generally driven by electric motors, in the past with DC drives, but today mostly with high-speed frequency-controlled AC motors.

DC motors are less frequently used today. However, they still have their advantages for special applications and are therefore requested from us again and again.

Are you looking for an electric motor for your plant? We not only have DC motors on offer!

Electric motors are an essential part of mining and mineral processing. They drive large equipment such as crushers, mills and hoists, but also generators, compressors or pumps. MENZEL offersboth DC motors and 3-phase motors up to 13.8 kV and 25000 kW.

Your are looking for mining hoisting drives - DC or AC motors? Send us your inquiry today!