Why is water jacket cooling (IC 71W) ideal for ships?

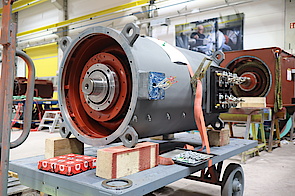

Since the three electric motors required are to be used in a ship's engine room, they were designed with IC 71W cooling. This efficient water jacket cooling ensures reliable motor performance even under high load changes and in particularly confined spaces.

Their high corrosion resistance makes the motors particularly suitable for maritime and industrial environments. In addition, our water-cooled motors are particularly energy-efficient and low-maintenance. They can be easily integrated into existing systems, reducing long-term operating costs and guaranteeing high reliability.

Technical monitoring for maximum operational safety

At the explicit request of the shipbuilding company, additional sensors were installed in all three squirrel cage motors to monitor the vibration behavior of the rotor and the heat development of the bearings. This enables the customer to monitor the behavior of the motor during operation. In addition to meeting the customer's requirements, MENZEL also fulfilled all the test criteria of the Registro Italiano Navale for RINA certification.

RINA certification – A mark of quality for maritime safety

The Registro Italiano Navale is an Italian classification society that inspects ships, maritime components, and technical systems for safety, environmental standards, and technical performance. It issues certifications that comply with international regulations and ensure the safe operation of ships. A RINA approval confirms that a ship or ship component, such as an electric motor, meets all necessary quality and safety requirements.

Powerful technology – the most important specifications at a glance

Key performance data for the three squirrel cage motors supplied:

- Type: 3-phase squirrel cage, MEBKSW355-04

- Standard: IEC / EN 60034-1

- Rated power: 500 kW

- Rated voltage: 690 V

- Rated speed: 1485 min-1

- Design: IM 3011 (IM V1)

- Number of poles: 4

- Protection class: IP 55

- Cooling: IC 71W (water jacket cooling)

- Weight: 2,425 kg

Applications for water-cooled IC 71W engines on ships

Thanks to their ease of maintenance, high power density, and durability, IC 71W motors are the preferred choice in demanding environments where high temperatures, confined spaces, or harsh operating conditions prevail. Water-cooled IC 71W motors are frequently used in shipping, e.g., for bow thrusters or stern thrusters, as they deliver high starting torque and operate reliably even under high loads. Water-cooled IC 71W motors are also frequently used in ballast pump systems or for hydraulic drives on ships, such as those found in cranes, winches, and steering systems.

Let us advise you – find the perfect motor for your application!

Why is the IC 71W water cooling system so efficient?

The key feature of an IC 71W squirrel cage motor is water jacket cooling. This technology uses the water jacket as a closed-loop system to effectively dissipate excess heat from the motor. The motor is installed in a water jacket that is continuously flushed with cold water, which absorbs the heat and dissipates it via a heat exchanger. This process makes it possible to keep the motor temperature constant and low, even under intensive operating conditions. This leads to a significant reduction in energy consumption, which has a positive effect on the energy efficiency of the entire system.

High engine performance in the smallest of spaces

The compact design of the water jacket cooling system allows the motors to deliver high performance in a small space without overheating. This offers a decisive advantage in confined engine rooms or in environments where space is limited.

Uniform operating temperature, less wear

Another advantage of water jacket cooling is its ability to maintain a consistent operating temperature, thereby preventing temperature fluctuations. This not only ensures higher performance efficiency, but also extends the service life of the motor. Fewer temperature fluctuations mean less stress on the windings, bearings, and other sensitive components, which reduces maintenance requirements and extends maintenance intervals. The absence of fans contributes to the low-noise and low-vibration operation of IC 71W motors.