Challenge: High safety requirements with minimal lead time

The customer urgently required a replacement for a compressor drive operating in a hazardous area (Zone 1). In addition to complying with the protection class II 3G Ex pzc IIB T3 Gc, fast availability was critical, as the compressor plays a key role in the production process. The new motor had to fit exactly into the existing footprint, including foundation dimensions, flange positions, and connection geometries.

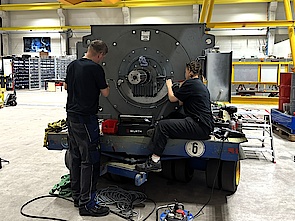

All necessary modifications to the stock motor had to be completed within three weeks. MENZEL engineers were on-site even before order placement to review the installation situation and clarify all technical details.

Solution: Perfect combination of stock availability, engineering expertise, and Ex-p know-how

MENZEL successfully executed the project because both the suitable squirrel-cage motor from the MEBKSW series and the pressure-encapsulated Ex-p system were immediately available from stock – a decisive advantage over many other manufacturers.

The stock motor was extensively adapted to the application and installation site. The housing was equipped with purge flanges, allowing the motor to be flushed with a non-ignitable gas mixture before start-up, while overpressure during operation prevents the ingress of hazardous gases. The motor was certified II 3G Ex pzc IIB T3 Gc, and all testing according to applicable Ex standards was performed in our in-house certified test facility.

Additional modifications included:

- Conversion to cooling type IC 81W (water-cooled)

- Mechanical adjustment of frame size from 560 to 630

- Relocation of terminal boxes

- Preparation of the star-point terminal box for current transformers

- Adjustment of bearing flange connections

- Installation of vibration sensors

Thanks to close cooperation between engineering, manufacturing, and quality assurance, all mechanical and electrical work was completed within three weeks and delivered via special truck. MENZEL also offered technical supervision for commissioning.

Technical data of the 2-pole AC asynchronous motor

- Type: MEBKSWP560-02 AC Motor

- Ex Protection: II 3G Ex pzc IIB T3 Gc

- Application: Compressor drive

- Rated Power: 3,550 kW

- Rated Voltage: 10,500 V

- Rated Speed: 2,988 min⁻¹

- Construction Type: IM B3

- Protection Class: IP 55

- Cooling Type: IC 81W (Totally Enclosed Water to Air Cooled, TEWAC)

- Weight: 12,500 kg

MENZEL Ex-p strengths: fast, flexible, certified

This project demonstrates how MENZEL can deliver pressure-encapsulated Ex-p motors even under extreme time pressure. By keeping both base motors and Ex-p components in stock, we can meet short lead times for Zone 1 AC motors that few other manufacturers can achieve.

Our engineers expertly handle both mechanical and electrical customizations, as well as integration of overpressure encapsulation, pressure monitoring systems, and various cooling concepts. TÜV-certified in-house manufacturing ensures the highest safety: from leakage and purge testing to electrical integration and full documentation.

This makes MENZEL one of the few manufacturers capable of rapidly converting standard motors into fully compliant pressure-encapsulated Ex-p motors for Zone 1 applications.

Ex motors require experience and sometimes fast solutions

With a combination of stock availability, technical flexibility, and certified Ex expertise, MENZEL ensures that even time-critical projects with the highest safety requirements are executed reliably.

Do you need a pressure-encapsulated Ex-p motor quickly – customized for your plant and fully compliant with current standards? Our experts provide support from design to commissioning.

Contact us now to request your Ex-p solution!