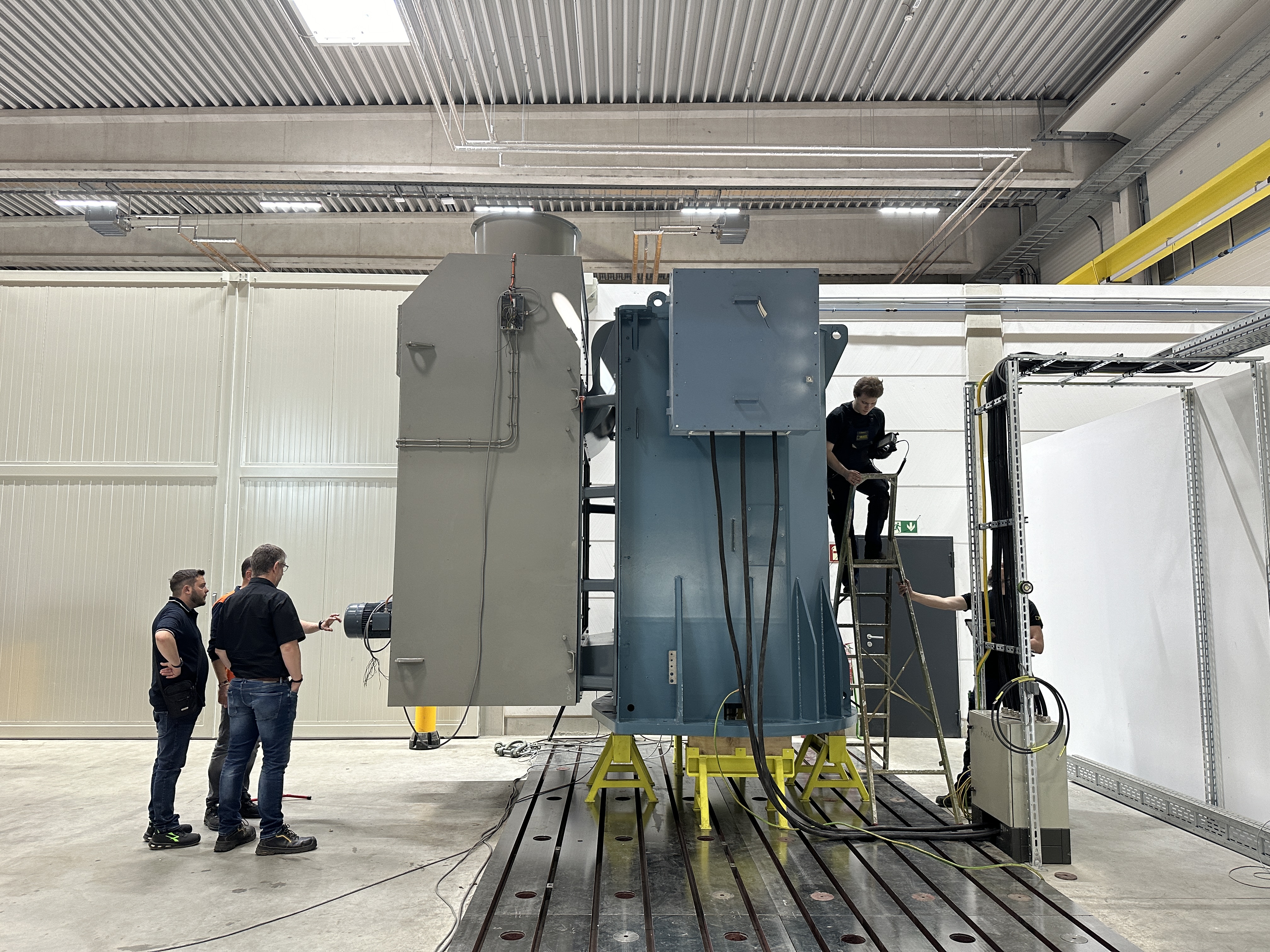

Precision Engineering – Proven on the Test Bench

The newly developed MEBKSL three-phase squirrel cage motor is designed in vertical mounting position IM 3011 (IM V1) with a striking shaft height of 710 mm. It‘s performance specifications are equally impressive:

- Rated Power: 650 kW

- Rated Voltage: 690 V

- Rated Torque: 16,731 Nm

- Number of Poles: 12

- Cooling Type: Converted from IC 86W (water-cooled) to IC 666 (air-cooled)

At MENZEL’s in-house test field, the motor’s performance was verified across all load points – ensuring reliable and continuous operation in its demanding environment.

Custom Solutions – Delivered at Record Speed

A key factor in the project’s success was MENZEL’s extensive inventory: a suitable 12-pole converter motor with 31-Hz star winding was already in stock, enabling an exceptionally fast turnaround. Only seven weeks passed from the initial inquiry to the motor’s arrival on site.

While the electrical design required only minor on-site parameter adjustments, extensive mechanical modifications were carried out by MENZEL’s engineering team:

- A custom adapter flange was manufactured for seamless pump integration

- The shaft dimensions were modified

The motor’s cooling system was redesigned, including a custom-built air cooler and internal airflow adjustments

To ensure long-term durability under aggressive ambient conditions, the motor was also finished with a special protective coating in MENZEL’s inhouse paint shop. The finished motor meets IP55 protection class requirements.

Are you interested in further information or a customized motor offer?