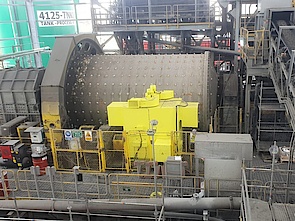

A 2,980 kW (4,000 HP) asynchronous squirrel cage motor was urgently delivered and customized for a mill application at a goldmine in the Peruvian Andes, located at an extreme altitude of 4,200 meters. Designed for 4,160 V and 60 Hz operation, the replacement motor runs at 894 rpm. It was installed to restore critical mill functionality following a sudden equipment failure.

⇓ Watch below a behind-the-scenes video, to witness the final tests of the custom-engineered 2,980 kW HV motor at MENZEL’s in-house load test field ⇓

Reliable Motor Solutions for Demanding Mining Applications

Electric motors are a vital component in the mining industry, powering everything from crushers and mills to conveyors and ventilation systems. In such harsh environments, motors must withstand dust, moisture, vibration, and extreme temperatures—often at high altitudes. Key factors in selecting a suitable motor for mining operations include high reliability, robust construction, efficient cooling, ease of maintenance, and compatibility with variable frequency drives (VFDs) for flexible speed control. Quick availability and adaptability to existing installations are also essential, particularly when unplanned downtime occurs.

In one recent case, a replacement motor was urgently required to drive a mill at a goldmine in the Peruvian Andes, situated at an altitude of 4200 m above sea level. The original motor had failed unexpectedly, halting critical operations. A suitable motor was sourced from MENZEL stockand delivered on an express basis. However, several custom modifications were needed to ensure full compatibility with the existing setup.

Project overview and motor specifications

To resume operations swiftly, a stock IEC‑compliant motor (MEBKSF630‑08) was deployed with the following data:

- Rated power: 2,980 kW (4,000 HP)

- Voltage: 4,160 V

- Frequency: 60 Hz

- Speed: 894 rpm, 8‑pole

- Cooling: IC 06 forced ventilation (external fan)

- Protection: IP W24

- Mounting: IM 1001 (IM B3)

- Weight: 12,800 kg

Need a Motor Fast? Speak Directly to Our Engineers!

Get expert advice on urgent replacements, custom modifications, and high-altitude solutions—without delay.

Tailored Modifications for Harsh High-Altitude Conditions

The in-stock motor’s cooling system was converted from IC611 to IC06 (IPW24) with external fans, to guarantee reliable operation in the thin mountain air. Electrically, the motor was rewired for double-delta configuration (4160 V, 60 Hz) for VFD operation.

Mechanically, the BS shaft end was removed, and shaft dimensions were adjusted as needed. Custom-made base plates were installed to match the mounting hole pattern and frame height of the existing foundation. Thanks to these tailored modifications, the replacement motor was quickly integrated into the plant, minimizing downtime and restoring full operational capacity. These measures ensured full operational compatibility and high reliability at 4200 m above sea level.

A True Engineering Challenge: VFD Operation at 4,200 m Altitude

Operating a motor on a variable frequency drive (VFD) at 4,200 m above sea level presents complex technical challenges that demand a holistic approach—covering cooling, insulation systems, electrical design, and mechanical integration. It also requires proven experience in delivering customized solutions under extreme conditions. MENZEL provides exactly this expertise.

“Not only did we receive a powerful replacement motor on short notice from MENZEL, but their engineering team adapted it perfectly to our setup. Direct contact with an engineer made all the difference.”

Spare unit and customer testing experience

Due to the success and critical role of the installed motor, the client has already ordered a second identical motor as a spare for the same application. Both motors underwent comprehensive type and load testing at MENZEL’s Berlin test‑field, where the client was present to witness the test sequences in real time—ensuring full confidence before shipping and installation.

The successful customization, witnessing, and acceptance of both motors by the client resulted in exceptional operational readiness and peace of mind. The second motor now stands as a ready spare to support ongoing continuity in the remote high‑altitude installation.

MENZEL Berlin Test‑Field Capabilities for Engineers

MENZEL’s state‑of‑the‑art load test facility in Hennigsdorf near Berlin, Germany supports vendor‑independentmotor testing up to13.8 kV and 1,800 kW under load, with idle tests up to 10,000 kW, and frequencies up to 120 Hz. Testing equipment includes 6 kV converters, rotary converters up to 13.8 kV, precision load resistors, and Hottinger‑Baldwin torque flanges rated up to 30 kNm at speeds up to 12,000 rpm.

The facility features two large clamping plates (12 × 5 m and 9 × 3 m), an 80 t crane, hook height of 7.5 m, and a sound‑proof, heated visitor lounge that enables clients to observe testing procedures directly. All test reports comply with EN 60034 standards, including temperature rise and load testing protocols.

Are you searching for reliable and customized motor solutions for demanding mining applications? Talk to the people who know the motor best. Immediate technical support and tailored solutions for mining and heavy industry.