Solution: Modular design with customized engineering

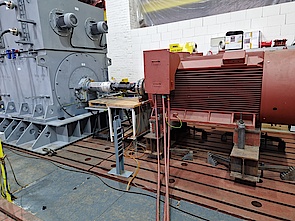

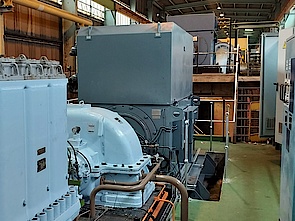

MENZEL Elektromotoren developed a high-voltage compressor motor in a modular design. The base frame (3 t), motor (14.7 t), and cooler (2 t) were manufactured, delivered, and installed separately. This approach allowed compliance with the crane’s load limit without any modifications to the existing plant.

The new motor was based on MENZEL’s proven MEBKSW series, known for its high power density, flexibility in cooling options, and robust construction.

Technical specifications of the delivered compressor motor:

- MENZEL motor type: MEBKSW630/1120-06

- Standard: IEC/EN 60034-1

- Rated power: 6,000 kW (6MW)

- Rated voltage: 11,000 V (11 kV)

- Speed: 988 rpm

- Frequency: 50 Hz

- Mounting type: IM 1001 (IM B 3)

- Frame size: 630

- Degree of protection: IP 54

- Cooling method: Air-water cooling (IC 86W)

- Weight: 19,750 kg (motor 14,700 kg, cooler 2,000 kg, adapter frame 3,000 kg)

Background: Gas compressors and drive requirements

Gas compressors are key components in process and energy engineering. They compress gases such as oxygen, nitrogen, or hydrogen for applications in chemicals, metallurgy, power generation, or food technology.

The drive motors for these compressors must meet the highest standards:

- High starting torque for compressor operation

- Continuous duty (S1) with maximum reliability

- Thermal resilience and secure cooling

- Vibration and shock resistance

- Explosion protection depending on gas type and zone

A replacement motor therefore needed to be technically compatible and capable of being installed under challenging on-site logistical conditions.

Quality assurance and final motor testing

As with all MENZEL electric motors, the compressor motor underwent comprehensive testing in the in-house load test field. The customer was present for acceptance and could observe the motor’s performance live.

For customer visits, a modern lounge with a view of the test field is available – a service that provides transparency and builds trust.

Conclusion: Customized motor solutions for every challenge

Thanks to the modular design, the motor was safely installed despite the tight logistical constraints. The customer received a fully functional replacement for the existing motor – mechanically and electrically compatible, without modifications to the plant.

This project demonstrates how MENZEL leverages technical expertise, flexibility, and customer focus to deliver tailored solutions. We provide custom high-voltage motors for critical applications, even where standard solutions reach their limits.

Your project – our solution

Whether it’s a replacement motor, retrofit, or fully customized new build: MENZEL Elektromotoren develops low-, medium-, and high-voltage motors precisely tailored to your plant and requirements.

Contact us today to discuss your technical challenge. Our engineers will advise you personally and identify the optimal drive solution.