The challenge: short operating times, many motor starts

MENZEL is always the right partner when looking for tailored drive solutions for specific industrial applications! Above all, skills in the field of slip ring rotor motors for producing a replaceable motor were required in the case of the Göttingen-based research and development center for aerospace experiments.

The client wanted an improvement in performance in part of what is known as the transonic wind tunnel, which until then had been driven via a squirrel cage motor. The challenge: The transonic wind tunnel is a test operation with typically short operating times and frequently reoccurring starts. For necessary cooling of the original motor to take place, plant components were always subject to mandatory pauses lasting hours. These waiting times should no longer occur in the future.

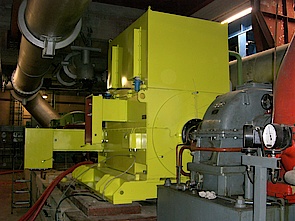

Our solution: Replacing the squirrel cage motor with a 5400 V slip ring motor slip ring motor

After a site inspection by MENZEL engineers, a requirements profile was worked on together with the client. The solution for this drive problem was to replace the present squirrel cage motor with a tailored slip ring rotor motor.

By carrying out a personal on-site visit we can often provide clients with additional recommendations for their industrial plants.

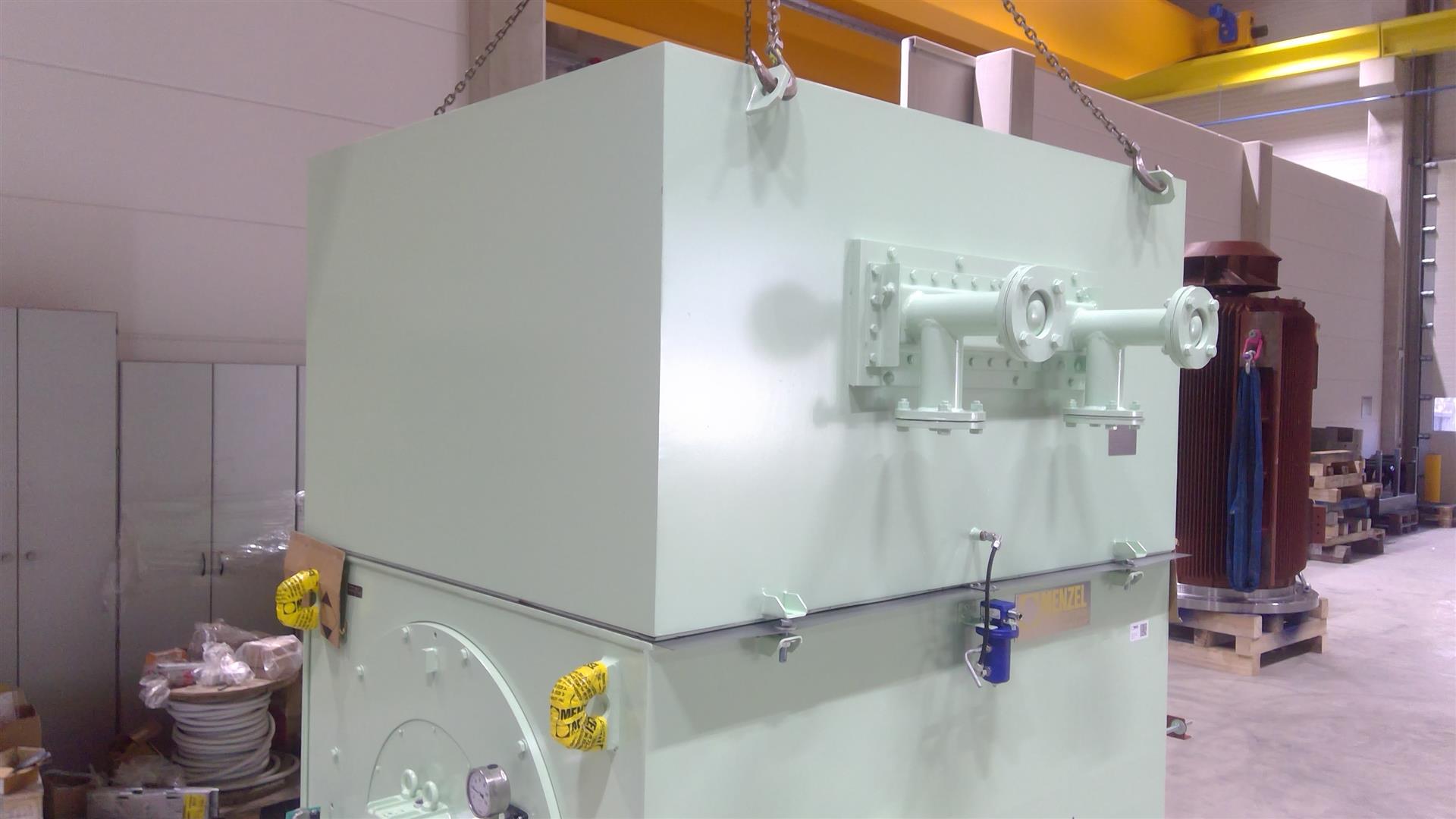

The design advantage of the three-phase slip ring rotor is a practically unlimited number of starts even when warm. This means the plant operator has the opportunity to carry out as many attempts in quick succession without the waiting times mentioned previously. When producing the custom motor, the on-site conditions (foundation, cooling water connections, supply lines, etc.) are observed accurately. The new slip ring rotor motor fitted perfectly on the old foundation.

A team from MENZEL also carried out assembly and commissioning of the motor - a service we provide to all our clients worldwide.

Motor data of the three-phase slip ring motor

- Type MEBSSW560F-04

- Rated power 3,000 kW

- Rated voltage 5,400 V

- Frequency 50 Hz

- Poles 4

- Rated speed 1,485 rpm

- Mounting IM B3

- Protection IP 55

- Cooling IC 81W

MENZEL slip ring motors are available as low, medium and high voltage motors. An overview of the slip-ring motors we offer can be found here.

Our strength is the delivery of tailored drive solutions for industrial plants of all kinds. Client-specific designs and tailored advice belong to our service concept for plant manufacturers and operators worldwide.

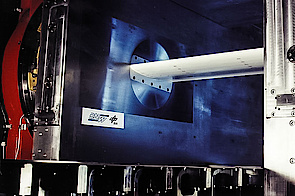

The transonic wind tunnel for aerospace experiments

The "TWG" is a transonic wind tunnel for aerospace experiments (sub-, trans-, and supersonic speeds). The wind tunnel is operated by the Deutsch-Niederländische Windkanäle (DNW) foundation, a joint subsidiary of the Deutsches Zentrum für Luft- und Raumfahrt (DLR) and the Netherlands Aerospace Center (NLR) founded in 1976. The TWG was integrated into the DNW foundation in 2000.

The focus of the foundation is to provide its clients with a wide range of wind tunnel and simulation technologies. To do so, it operates several wind tunnels in various locations, of which four are in Göttingen. Göttingen is considered to be the cradle of modern aerodynamics. The first state aeronautical research facility was already founded here in 1907.

You are looking for custom motors for your industrial plant?

We are experts for low, medium, and high voltage industrial motors and we look forward to your enquiries.