MENZEL motor windings

Windings are the heart of any industrial motor. We realize the most diverse of designs for our new machines.

The high-quality windings of our MENZEL three-phase asynchronous motors (low-voltage, medium-voltage, and high-voltage) and direct current motors are designed in accordance with the latest state of technology. Often, new windings are also used as part of the modification of motors in order to enable quick adjustments.

MENZEL motor windings have been developed for high mechanical stresses. For this reason, our industrial motors can also be used in the most difficult environments and for really hard work in mills, crushers, and power stations. In the motor winding shop, we use only the latest insulation materials and top-quality wires.

A motor winding shop for challenging new windings

At our motor winding rooms, we have PC-controlled winding machines, a whole range of wire thicknesses for small to large industrial motors, impregnation plants, and drying ovens that are also suitable for larger electric motors.

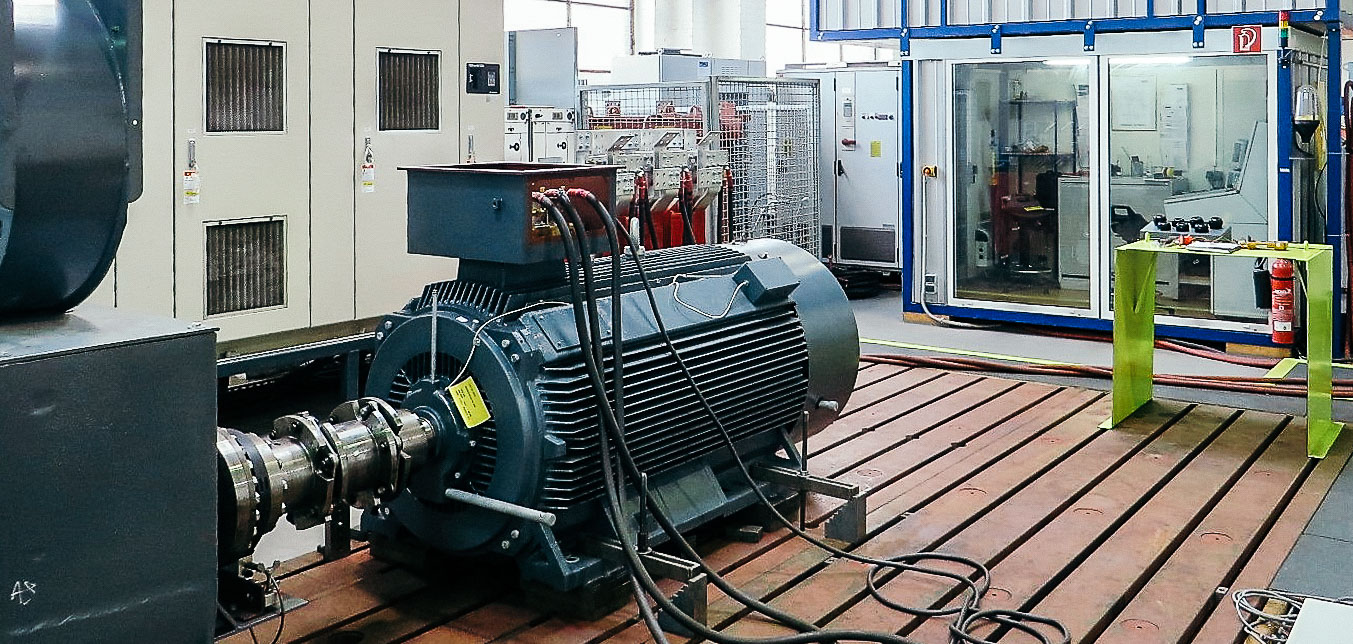

The new windings are thoroughly checked during the production phase. At the end of the production process, each MENZEL electric motor is subjected to an extensive test run in our load test facility. In this way, we ensure the quality of all of our high-voltage and low-voltage windings.

Your advantages with us

DIN EN ISO 9001

certified

Experts for industrial motors

Up to 13,800 V

Custom design

and individual adaptations

24h emergency service

Short delivery times

Own manufacturing facilities

in Germany

Worldwide locations

and excellent partners

Possible winding types

- Form windings for medium-voltage and high-voltage motors using VPI procedure (thermal classes: F and H; voltage range: 13,800 V; power range: To 20,000 kW)

- Form windings for medium-voltage and high-voltage motors using resin-rich procedure (thermal class: F; voltage range: To 13,800 V; power range: To 20,000 kW)

- Converter-suitable form windings for low-voltage motors (thermal classes: F and H; voltage range: Up to 1,000 V; power range: To 5,000 kW)

- Converter-suitable fed-in windings for low-voltage motors (thermal classes: F and H; voltage range: To 1,000 V up to around 1,000 kW, thereafter as form winding)

- Rotor windings (thermal classes: F and H; voltage range: To 3,000 V)

- Rotor windings for all three-phase machines (thermal classes: F and H)

- Direct current stator windings (thermal classes: F and H, for the complete power range)

- Direct current armature windings (thermal classes: F and H, for the complete power range)

- Direct current bar windings (thermal classes: F and H)